Tesla Model Y Elon Musk production manufacturing revolution: This groundbreaking analysis delves into the intricate process behind the Model Y’s production, exploring Elon Musk’s pivotal role in shaping the electric vehicle manufacturing landscape. From the sourcing of raw materials to the final assembly, we’ll examine the technological advancements, challenges, and solutions employed in this revolutionary approach. The impact on global economies and the environment will also be explored, providing a comprehensive view of this significant transformation in the automotive industry.

The Model Y’s production stands as a testament to the power of innovation and automation in manufacturing. By analyzing Elon Musk’s leadership style and strategic decisions, we gain valuable insights into the challenges and triumphs of scaling production in a rapidly evolving industry. This exploration offers a unique perspective on the future of electric vehicle manufacturing and its implications for the global automotive market.

Tesla Model Y Production Overview

The Tesla Model Y, a pivotal model in Tesla’s growth trajectory, showcases a unique approach to automotive production. This approach prioritizes automation, innovative supply chain management, and a relentless focus on efficiency. Its production process stands in stark contrast to traditional methods, demonstrating a significant shift in the industry.Tesla’s Model Y production employs a sophisticated blend of technologies, from raw material sourcing to the final assembly stage.

This integrated system emphasizes minimizing waste, maximizing output, and maintaining stringent quality standards. The result is a production model that is both efficient and technologically advanced.

Raw Material Sourcing and Component Procurement

Tesla’s Model Y production relies heavily on a robust supply chain. The company has established partnerships with key suppliers, enabling a streamlined and reliable flow of components. This process encompasses the careful selection of materials and vendors, ensuring high quality and consistency throughout the manufacturing process.

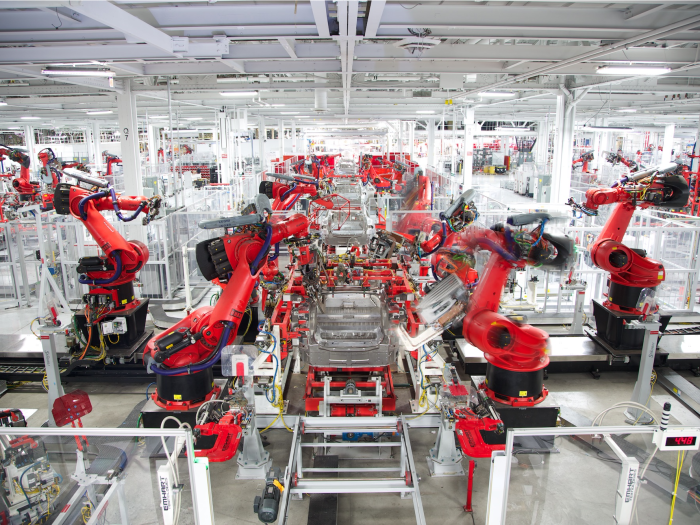

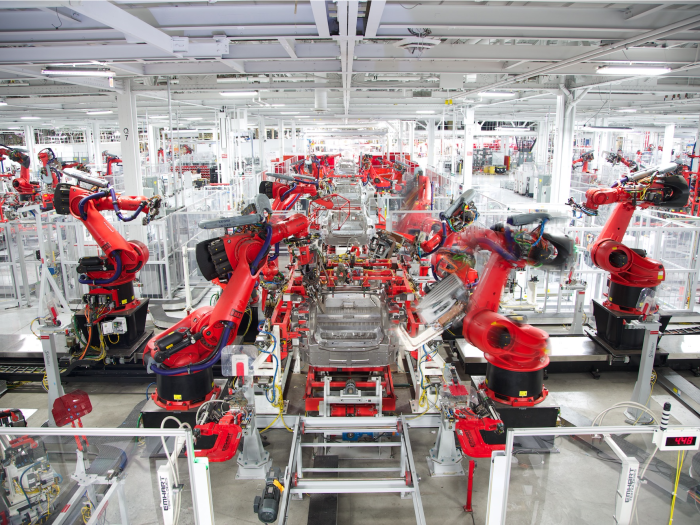

Assembly Line Operations

Tesla’s Model Y assembly lines are characterized by high levels of automation. Robotic arms and automated systems handle numerous tasks, from welding and painting to final assembly. This level of automation allows for a faster production cycle and improved precision compared to traditional methods. The layout of the assembly lines is optimized for smooth workflow and efficient material flow.

This layout reduces bottlenecks and enhances overall production speed.

Quality Control Measures

Tesla implements rigorous quality control measures at every stage of Model Y production. These measures include rigorous testing procedures, utilizing advanced sensors and automated systems to identify defects early in the process. The goal is to ensure the highest possible quality and minimize the risk of defects reaching the end consumer. This commitment to quality control is vital for maintaining Tesla’s brand reputation and customer satisfaction.

Comparison to Traditional Automakers

Traditional automakers often rely on a more labor-intensive approach to production, with a greater emphasis on human labor in various stages. Tesla, on the other hand, prioritizes automation, aiming to reduce production costs and improve efficiency. This difference is reflected in the overall production cycle time and the ability to adapt to fluctuating demand.

Technological Advancements

Tesla’s Model Y production leverages cutting-edge technologies, including advanced robotics, AI-powered systems for predictive maintenance, and 3D printing for certain components. These technologies contribute to increased efficiency, faster production rates, and higher quality standards. The utilization of advanced sensors allows for real-time monitoring of the production process, enabling quick identification and resolution of any issues.

Supply Chain Management

A well-managed supply chain is crucial for Tesla’s Model Y production. The company actively manages its supply chain to ensure a reliable flow of materials and components. This includes maintaining relationships with key suppliers, optimizing logistics, and strategically locating production facilities to minimize transportation costs and time.

Scale and Efficiency of Production Facilities

Tesla’s production facilities are designed with efficiency in mind. The facilities are large-scale, allowing for significant output. This scale enables Tesla to meet the increasing demand for the Model Y while maintaining cost-effectiveness. The layouts of the facilities are optimized for streamlined workflows, minimizing material handling and maximizing the utilization of space.

Elon Musk’s Impact on Production: Tesla Model Y Elon Musk Production Manufacturing Revolution

Elon Musk’s leadership at Tesla has undeniably revolutionized the automotive industry, and the Model Y production exemplifies this impact. His unique approach to leadership, combined with a visionary approach to electric vehicle manufacturing, has shaped the Model Y’s design, production process, and the challenges Tesla faced during its scaling. Musk’s relentless pursuit of innovation has had a profound influence on Tesla’s production methods, though not without its share of difficulties.Musk’s leadership style, often characterized by a demanding and high-pressure environment, has both fostered rapid progress and generated considerable controversy.

This style, while arguably controversial, has been instrumental in pushing Tesla to achieve production milestones, particularly in the Model Y’s development. His emphasis on efficiency and automation has been a key driver in reducing production costs and improving output.

Musk’s Leadership Style and its Impact on Model Y Production

Musk’s leadership style is characterized by a hands-on approach, a relentless drive for innovation, and a commitment to pushing the boundaries of what’s possible. This has had a direct impact on the Model Y’s production process. His focus on speed and efficiency has driven the implementation of advanced automation technologies and lean manufacturing principles. He prioritizes speed, often at the expense of other considerations.

Elon Musk’s Tesla Model Y production is a fascinating example of revolutionary manufacturing, but sometimes even the most efficient systems lose data. Thankfully, if you’ve accidentally deleted files on your Android 12 phone, you can potentially recover them using a built-in trash bin or through third-party solutions like those described in google android 12 trash bin recover lost deleted files.

This highlights the importance of both physical and digital efficiency in today’s fast-paced world of innovation, much like the Model Y’s mass production.

Musk’s Vision for Electric Vehicle Manufacturing and its Influence on Model Y Design and Production, Tesla model y elon musk production manufacturing revolution

Musk’s vision for electric vehicle manufacturing is deeply rooted in his belief in the potential of sustainable transportation. This vision has influenced the Model Y’s design, aiming for both affordability and performance. The emphasis on battery technology, particularly in the Model Y, reflects Musk’s commitment to making electric vehicles accessible to a wider range of consumers. This vision, coupled with a focus on rapid scaling, has often led to challenges in maintaining quality control and meeting consumer expectations.

Musk’s Approach to Innovation and its Effects on Model Y Production

Musk’s approach to innovation emphasizes the rapid prototyping and implementation of new technologies. This has resulted in a dynamic and rapidly evolving production process for the Model Y. The introduction of new technologies and production methods often requires significant retraining of employees, creating a dynamic work environment. The incorporation of advanced robotics and automation, influenced by Musk’s drive for innovation, has dramatically altered the production lines.

Challenges Faced by Tesla in Scaling Model Y Production

Scaling Model Y production presented significant challenges for Tesla. Supply chain disruptions, material shortages, and workforce training issues were some of the key difficulties. The rapid growth of production often outpaced the capacity to adapt the infrastructure and supply chain. Furthermore, maintaining consistent quality while scaling production was a significant concern.

Examples of Musk’s Strategies for Improving Production Efficiency

Musk’s strategies for improving production efficiency are diverse and often unconventional. His emphasis on automation and robotics has been instrumental in streamlining production lines. He also implemented initiatives aimed at reducing waste and improving material flow. Examples include optimizing factory layouts, implementing real-time production monitoring systems, and implementing more flexible staffing strategies.

Comparison of Musk’s Influence on Tesla’s Production with Other Influential Figures in the Automotive Industry

Comparing Musk’s influence with other automotive industry leaders reveals unique characteristics. While other figures like Henry Ford revolutionized assembly lines, Musk’s impact has been more profound in terms of technology integration and a commitment to sustainability. His focus on software and technology integration is a defining aspect of his approach, setting him apart from more traditional automotive executives.

Manufacturing Revolution Implications

The Tesla Model Y’s production exemplifies a profound shift in automotive manufacturing, driven by Elon Musk’s vision and innovative techniques. This revolution is not just about building cars faster; it’s about fundamentally altering the way vehicles are conceived, designed, and produced, impacting cost, quality, and environmental footprint. This approach is not without its challenges, but the potential for widespread adoption is significant.The Model Y’s manufacturing process has been streamlined, integrating automation, robotics, and advanced materials to achieve unprecedented efficiency.

This approach, however, is not without its challenges and the impact on other manufacturers is varied. The success of this new model hinges on the ability to maintain quality and reduce costs while maintaining production speed.

Key Components of the Manufacturing Revolution

The manufacturing revolution applied to the Model Y hinges on several key components. These include advanced automation systems, using robots for repetitive tasks, allowing for greater speed and consistency. Design for manufacturability (DFM) principles are employed, optimizing the vehicle’s design to facilitate assembly and reduce material waste. Utilizing readily available and affordable materials, such as aluminum and carbon fiber composites, minimizes production costs.

Finally, a robust supply chain, ensuring a reliable flow of materials and components, is crucial for maintaining production output.

Impact on Model Y Production

The manufacturing revolution has profoundly impacted Model Y production. The integration of robotics and automation has significantly reduced production time. The use of advanced materials and DFM has lowered production costs, while consistent quality control procedures maintain high standards. This combination of factors has allowed Tesla to scale production volumes efficiently. This impact, however, has been felt across the board.

Impact on Tesla vs. Other Automakers

Tesla’s manufacturing revolution has presented a stark contrast to traditional automotive production methods. While other manufacturers are adopting some aspects of automation, Tesla’s approach is more radical and comprehensive. This is reflected in Tesla’s ability to adapt to fluctuating demand, offering a greater degree of flexibility in their production lines.

Potential Future of Manufacturing

The Model Y’s manufacturing methods suggest a future where automation and advanced materials are the norm. Production lines will be more dynamic and responsive to market demands, while the use of renewable energy in manufacturing facilities will reduce the environmental impact. This is evident in the significant advancements in EV manufacturing.

Timeline of Significant Changes in EV Manufacturing (Model Y Focus)

- 2017-2018: Introduction of advanced automation in Tesla’s Fremont factory, laying the groundwork for the Model Y production.

- 2019: Implementation of DFM principles for the Model Y, leading to reduced assembly time and improved quality.

- 2020-2021: Expansion of Gigafactories and integration of new technologies, enabling increased production capacity for the Model Y.

- 2022-present: Continuous optimization of the Model Y’s production process, incorporating feedback from real-world usage and improving efficiency further.

Comparison of Manufacturing Methods

| Feature | Traditional Car Manufacturing | Model Y Manufacturing |

|---|---|---|

| Speed | Relatively slow, reliant on manual labor | Faster, leveraging automation and robotics |

| Cost | Higher due to labor and material costs | Potentially lower due to automation and efficient material use |

| Quality | Can vary based on human error | High, controlled by automated processes and quality checks |

| Environmental Impact | Higher due to energy consumption and waste | Potentially lower due to the use of renewable energy and sustainable materials |

Model Y Production Challenges and Solutions

Tesla’s Model Y, a pivotal vehicle in their expansion strategy, faced numerous production hurdles during its initial rollout. These challenges, stemming from a combination of supply chain complexities, technological advancements, and manufacturing intricacies, demanded innovative solutions to ensure efficient and timely production. Addressing these head-on was crucial for Tesla to maintain market share and solidify its position in the electric vehicle market.

Significant Production Challenges

Tesla encountered a multitude of challenges in the Model Y’s production process. These difficulties ranged from material sourcing and supply chain disruptions to complex assembly procedures and quality control issues. The rapid expansion of the Model Y’s production, coupled with the inherent complexities of manufacturing a cutting-edge electric vehicle, exacerbated these issues. The high demand for the Model Y, a testament to its appeal in the market, also amplified the need for efficient production methods.

Proposed Solutions and Anticipated Outcomes

To effectively address the production challenges, Tesla implemented a range of solutions. These solutions focused on enhancing efficiency, optimizing supply chains, and improving quality control. A key element was the strategic integration of technology and innovation throughout the production process.

| Challenge | Proposed Solution | Anticipated Outcome |

|---|---|---|

| Supply Chain Disruptions | Diversification of suppliers, establishing strategic partnerships with alternative materials providers, and optimizing logistics. | Reduced vulnerability to disruptions, increased supply chain resilience, and improved delivery timelines. |

| Complex Assembly Procedures | Implementation of automated assembly lines, standardized procedures, and enhanced training programs for employees. | Increased efficiency in the assembly process, reduced production errors, and improved worker productivity. |

| Quality Control Issues | Implementation of rigorous quality control measures, including advanced inspection techniques and real-time data analysis, and improved employee training and quality checks at each production step. | Enhanced product quality, reduced defect rates, and improved customer satisfaction. |

| High Demand and Production Rate | Increased factory capacity through the expansion of existing facilities and the construction of new manufacturing plants. Improved manufacturing processes through automation and optimization. | Increased production capacity, reduced lead times, and ability to meet consumer demand. |

Role of Innovation in Overcoming Challenges

Innovation played a pivotal role in tackling the Model Y’s production hurdles. Tesla, renowned for its forward-thinking approach, consistently sought to integrate new technologies and methodologies to streamline processes and enhance efficiency. This included the development of advanced robotics, AI-powered quality control systems, and optimized manufacturing processes. By constantly pushing the boundaries of what’s possible, Tesla aimed to create a more efficient and effective manufacturing system.

Use of Technology to Solve Production Challenges

Technology was instrumental in solving the challenges of Model Y production. From automated assembly lines to AI-driven quality control systems, technology enabled Tesla to enhance efficiency, reduce errors, and increase productivity. Advanced robotics and data analytics were crucial in optimizing production processes, reducing lead times, and improving decision-making. This approach underscores Tesla’s commitment to utilizing technology to drive innovation and enhance its production capabilities.

Elon Musk’s Tesla Model Y production is a fascinating example of modern manufacturing, showcasing a revolution in efficiency. While examining the intricacies of this revolution, it’s interesting to consider how societal shifts and control of resources play out in fictional dystopias. For instance, the novel “The Handmaid’s Tale” explores the devastating consequences of a patriarchal society, prompting critical questions about feminism and the future.

Ultimately, these contrasting perspectives on societal control, whether in the world of manufacturing or in dystopian fiction like does the handmaids tale hold up dystopia feminism fiction , offer a broader understanding of how we shape our world, and how seemingly disparate fields can intersect.

Addressing Supply Chain Disruptions

Tesla proactively addressed supply chain disruptions by diversifying its supplier base and developing strategic partnerships with alternative material providers. By not relying solely on a single source, Tesla mitigated the risk of shortages or price fluctuations. This proactive approach allowed Tesla to maintain production levels even during periods of global instability. For example, in the face of chip shortages, Tesla focused on securing alternative chip suppliers to maintain production.

This strategy highlights Tesla’s commitment to creating a resilient supply chain.

Global Impact of Model Y Production

The Tesla Model Y’s production has reverberated through the global automotive landscape, creating ripples across industries, economies, and even social structures. Its impact extends beyond the simple production of a vehicle; it’s a catalyst for change in how we think about transportation, sustainability, and economic development. This analysis will explore the multifaceted global impact of the Model Y’s production, examining its influence on various aspects of the world.The Model Y’s production has significantly altered the competitive landscape for the automotive industry.

The surge in demand for electric vehicles (EVs) and the subsequent production of the Model Y has forced traditional automakers to accelerate their own EV development programs. This competition fosters innovation and pushes the industry towards greater efficiency and lower costs for EV technology. This dynamic competition benefits consumers in the long run with more options and potentially lower prices for EVs.

Automotive Industry Transformation

The Model Y’s production, driven by Tesla’s innovative approach to manufacturing and supply chain management, has set a new standard for EV production. This includes the integration of automation, battery technology, and sophisticated software systems. Other manufacturers are now adapting and innovating to keep up, which is driving a wave of technological advancement across the industry. This trend is pushing for a shift from traditional combustion engine vehicles to a more sustainable and technologically advanced automotive sector.

Global Economic Impact

The Model Y’s production has had a significant impact on global economies. Tesla’s production facilities and supply chains have created jobs and stimulated economic growth in various countries. The ripple effect of the production process, from raw material sourcing to final assembly, has impacted numerous economies. The rise of EV manufacturing also spurs growth in supporting industries like battery production and charging infrastructure.

Environmental Sustainability

The Model Y’s production has highlighted the potential for a more sustainable automotive industry. While manufacturing processes have environmental impacts, the shift towards electric vehicles contributes to reducing greenhouse gas emissions. The Model Y’s production, along with other EVs, represents a step towards a lower carbon future. This impact is being felt in reduced air pollution in urban areas, with further advancements in renewable energy utilization.

Social Implications

The Model Y’s production has brought about changes in the way people view and use transportation. The affordability and accessibility of EVs, such as the Model Y, are influencing personal transportation choices, particularly in urban areas. This change is leading to a greater emphasis on mobility solutions that are both convenient and environmentally friendly.

Tesla’s Model Y, spearheaded by Elon Musk, is truly revolutionizing car production. Their innovative manufacturing processes are a game-changer, but to truly understand the depth of this transformation, you should check out the insightful analysis at come on over to the dark side. It delves into the intricacies of the supply chain and the overall impact on the automotive industry, ultimately shedding light on the broader implications of this manufacturing revolution.

The Model Y’s success is a testament to this groundbreaking approach.

Regional and Demographic Impact

| Region | Demographic Impact | Economic Impact |

|---|---|---|

| North America | Increased demand for skilled labor in EV manufacturing. | Stimulated economic growth in regions with Tesla facilities. |

| Europe | Increased interest in EVs, leading to more charging infrastructure. | Job creation in the automotive sector and related industries. |

| Asia | Increased demand for battery materials and components. | Growth in battery production and related manufacturing industries. |

This table illustrates a snapshot of how Model Y production affects different regions. The impact is significant and complex, affecting various demographics and industries across different locations.

Comparison with Other EV Models

The Model Y’s production has had a demonstrably large global impact. Compared to other EV models, the Model Y’s production scale and global reach have been a key driver of the overall shift toward EVs. The production of other models, like the Tesla 3 or other competitors, also has influenced the industry, but the Model Y has played a particularly significant role in accelerating the transition to electric vehicles.

Future of Tesla Model Y Production

The Tesla Model Y’s journey from initial production to its current global success is a testament to the power of innovation and meticulous planning. As the demand for electric vehicles continues to surge, the future of Model Y production hinges on adapting to evolving technological advancements and consumer expectations. Tesla must proactively address potential challenges to maintain its position as a leader in the EV market.The future of Model Y production will be shaped by several key factors, including the continued evolution of battery technology, the scaling of production facilities, and the incorporation of automation.

Strategies for improving production efficiency and managing the supply chain will play a crucial role in ensuring the Model Y remains a competitive and accessible option for consumers.

Potential Future Technological Advancements

Tesla’s commitment to innovation is evident in its continuous pursuit of advancements in battery technology, which directly impacts the production of the Model Y. This includes exploring solid-state batteries, which promise higher energy density and faster charging times. Improved battery chemistries and manufacturing processes can significantly reduce production costs and enhance the vehicle’s performance. Additionally, the development of more efficient electric motors and power electronics contributes to reduced energy consumption and enhanced vehicle range, benefiting the Model Y’s overall appeal.

Production Scaling and Facility Expansion

To meet anticipated demand, Tesla will likely continue expanding its existing Gigafactories and potentially establish new ones. This strategic expansion is crucial for accommodating the expected increase in production volume. Modernizing existing facilities with advanced robotics and automation technologies is a critical step in optimizing production lines and maximizing output. This approach ensures the Model Y remains a viable option for consumers globally.

Improving Production Efficiency

Optimizing the Model Y’s production process through advanced automation is essential. Implementing more sophisticated robotics, automated assembly lines, and artificial intelligence (AI) systems can dramatically increase efficiency and reduce production time. Predictive maintenance systems, for example, can minimize downtime and improve the overall production process.

Potential Changes to the Supply Chain

Tesla’s supply chain, crucial to the production of the Model Y, will need to adapt to the evolving global landscape. Diversifying sourcing of raw materials and components can mitigate potential disruptions from geopolitical instability or supply shortages. Stronger partnerships with suppliers who can deliver consistent quality and meet increasing demand will be vital for long-term success.

Potential Future Developments in Model Y Production

| Technology | Efficiency | Cost |

|---|---|---|

| Solid-state batteries | Higher energy density, faster charging | Potentially higher upfront cost, but likely lower long-term cost due to increased efficiency |

| Advanced automation | Reduced production time, higher output | Higher initial investment, but potentially lower long-term cost due to reduced labor costs |

| Optimized supply chain | Reduced lead times, greater resilience | Potential for lower costs due to economies of scale and reduced risks |

Examples of Tesla’s Future Innovation

Tesla could implement advanced 3D printing techniques for producing specific components, reducing material waste and speeding up production. Furthermore, integrating augmented reality (AR) systems for real-time monitoring and diagnostics during the assembly process will further optimize production efficiency. Utilizing AI-powered predictive maintenance models can proactively address potential issues before they impact production, minimizing downtime and optimizing output.

Last Recap

In conclusion, Tesla’s Model Y production represents a paradigm shift in automotive manufacturing. The innovative approaches and technological advancements, spearheaded by Elon Musk, have reshaped the industry. While challenges remain, the Model Y’s production underscores the potential of electric vehicles to drive a sustainable and efficient future. The ripple effects of this revolution extend far beyond the automotive industry, impacting global economies and environmental sustainability.