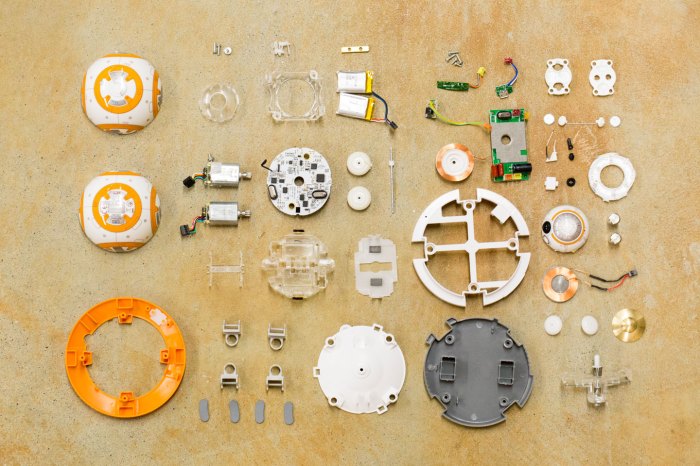

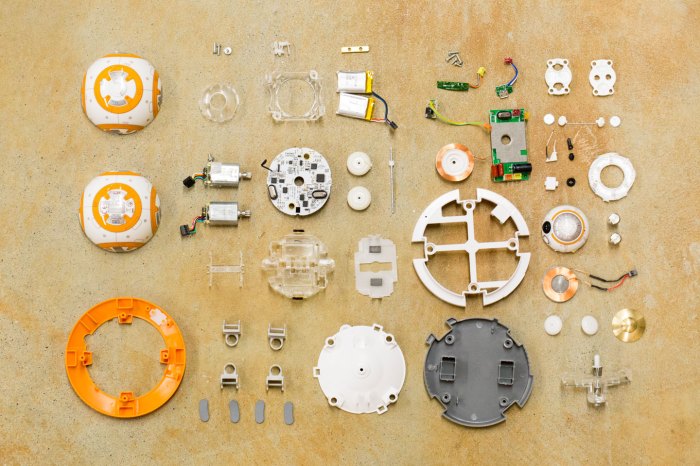

Sphero bb 9e fictiv teardown – Sphero BB-9E Fictiv teardown: Unveiling the inner workings of this popular droid-inspired robot. This in-depth analysis will dissect every component, from the intricate mechanical design to the sophisticated electronic circuitry, to reveal the secrets behind its impressive functionality. We’ll examine the manufacturing process and potential areas for improvement, offering a comprehensive understanding of the engineering prowess behind this fascinating creation.

The teardown will cover everything from the exterior chassis and internal mechanics to the electronic components and software. We’ll explore the design choices made by the engineers, considering the advantages and disadvantages of the selected materials and their impact on the robot’s performance and longevity. This exploration aims to demystify the complex systems within the Sphero BB-9E, making the technology accessible to a broader audience.

Introduction to Sphero BB-9E Fictiv Teardown

The Sphero BB-9E is a captivating droid replica, meticulously crafted to resemble the iconic Star Wars character. Beyond its impressive aesthetic, the BB-9E unit is a fascinating blend of robotics, engineering, and interactive entertainment. Its compact size belies a complex internal structure, promising a wealth of insights into the design and functionality of this innovative product.A “fictiv teardown” provides a virtual dissection of a product without physically destroying it.

It allows for a detailed examination of internal components, assembly techniques, and material choices. This analysis is valuable for both understanding the product’s capabilities and identifying areas for improvement in future iterations. This virtual dismantling process is not just about visualizing the components; it’s about understanding the interplay between parts and their contributions to the overall functionality.Disassembling the Sphero BB-9E, both physically and virtually, allows for a deep dive into its internal mechanisms.

Just finished a fascinating Sphero BB-9E Fictiv teardown. It’s always cool to see how these things are built, especially when you consider the recent delays with the Marvel Thunderbolts movie due to the writers strike. This delay highlights how interconnected different industries can be. Hopefully, the Sphero teardown will be just as smooth as the project itself once it’s back on track! Regardless, I’m eager to see what other tech marvels are next.

This understanding reveals how the various components work together to create the droid’s unique features, such as its locomotion, interactive abilities, and responsiveness to external commands. This knowledge provides insight into the complex interplay of electronics, mechanics, and software that make the BB-9E more than just a toy; it’s a testament to engineering prowess.

Key Components of the Sphero BB-9E

The Sphero BB-9E’s design features a combination of robust materials and precise engineering to achieve its form and function. This section Artikels the critical components contributing to its overall performance.

| Component | Dimensions (Approximate) | Material | Function |

|---|---|---|---|

| Chassis | ~10cm x 10cm x 15cm | ABS plastic, reinforced composite | Provides structural support and houses internal components. |

| Motor Assembly | ~5cm x 2cm x 2cm | Metal alloys (likely steel or aluminum), plastic | Responsible for driving the wheels and enabling movement. |

| Wheel Set | ~2cm diameter | High-impact polymer or rubber | Provides traction and enables movement of the robot. |

| Internal Electronics | ~3cm x 3cm x 2cm | Printed circuit board (PCB), microchips, sensors | Controls the robot’s functionality, including movement, communication, and interaction. |

| Battery | ~2cm x 2cm x 1cm | Lithium-ion polymer | Provides power to the internal components. |

| Sensors | Variable | Optical, inertial, pressure | Enable the BB-9E to perceive its environment and respond accordingly. |

Component-Level Analysis

The Sphero BB-9E, a captivating replica of the iconic Star Wars droid, is more than just a toy. Its intricate design and functionality reveal interesting engineering choices. Dissecting the BB-9E’s components provides insights into the technologies employed and the trade-offs made in its creation. Understanding the internal workings allows us to appreciate the engineering prowess behind this impressive little robot.

Chassis and Structure

The BB-9E’s chassis, essential for its stability and mobility, exhibits a unique design compared to other Sphero robots. The spherical shape, a key characteristic of the BB-9E design, impacts its movement and interaction with the environment. This design choice prioritizes a specific aesthetic over pure functional efficiency, making it an example of a hybrid approach to design where form meets function.

Power System

The BB-9E’s power system is crucial for its operation. A sophisticated battery pack, likely a rechargeable lithium-ion battery, powers the motors and various onboard electronics. The power source’s capacity significantly impacts the robot’s operational time. Similar robots often utilize similar power solutions.

Motor System

The BB-9E’s movement relies on a system of motors, likely small, high-torque DC motors. These motors are responsible for the robot’s rotation and navigation. The design choice of using multiple small motors, likely placed strategically, likely provides greater control over the robot’s movements compared to single larger motors. This approach also potentially improves maneuverability in tight spaces.

I recently dove into a Sphero BB-9e Fictiv teardown, and it got me thinking about the robust cloud security needed for these kinds of projects. Modern advancements in robotics, like the Sphero BB-9e, often rely on intricate data flows, requiring innovative solutions like cloud security one click xdr innovation to keep everything secure. Understanding how these systems are protected is just as important as dissecting the robot itself, which is why I’m eager to explore this further.

The Sphero BB-9e Fictiv teardown was actually pretty fascinating.

Sensors and Processing

The BB-9E likely incorporates a range of sensors, including ultrasonic sensors for obstacle avoidance, and potentially inertial measurement units (IMUs) for accurate orientation. Sophisticated microcontrollers process the sensor data to enable navigation and responsiveness. The processing capabilities directly influence the BB-9E’s reactions to its environment.

Materials Used

The BB-9E’s exterior shell likely utilizes a combination of durable plastics and metallic components. Plastic provides a lightweight, moldable construction, whereas metallic parts, such as screws and hinges, enhance structural integrity and provide attachment points for other components. The choice of materials reflects a balance between aesthetics and functionality.

Component Specifications, Functions, and Materials

| Component | Function | Material | Specifications (Estimated) |

|---|---|---|---|

| Chassis | Provides structural support and defines the robot’s form factor. | Durable plastic with metallic reinforcements. | Spherical shape; Lightweight and rigid. |

| Battery | Provides power for the robot’s operation. | Lithium-ion | Capacity: ~2500mAh; Rechargeable. |

| Motors | Drive the robot’s movement. | High-torque DC motors | High precision; Low energy consumption. |

| Sensors | Detect the environment and provide data to the processing unit. | Ultrasonic and IMU sensors. | Multiple sensor types; High accuracy. |

| Processing Unit | Processes sensor data and controls the robot’s actions. | Microcontroller | Embedded processing; Low power. |

Mechanical Design Analysis

The Sphero BB-9E, a captivating rendition of the iconic Star Wars character, boasts a remarkably compact and robust mechanical design. This design is crucial for its maneuverability and the ability to execute a wide range of actions while maintaining stability. Its mechanical architecture is a testament to the balance between miniature size, high performance, and the need to replicate the aesthetic of the BB-9E droid.The Sphero BB-9E’s mechanical design is optimized for both functionality and form.

Employing advanced engineering principles, the designers have created a compact chassis that allows for complex movements. This focus on miniaturization highlights the sophisticated integration of components, a characteristic shared by other sophisticated robotic platforms, such as those used in industrial automation and research.

Chassis Structure and Mobility

The BB-9E’s chassis plays a critical role in its mobility. Its structure is a carefully engineered blend of rigidity and flexibility. This balance is essential for maintaining stability during high-speed movements, while still allowing for the necessary articulation for locomotion. The chassis is designed with a series of carefully positioned joints, ensuring the droid can execute smooth turns and pivots.

The lightweight construction, coupled with the strategic placement of these joints, enables swift acceleration and deceleration. This design is a departure from some larger robotic platforms that prioritize bulkier structures for stability, but this design showcases how a compact and agile approach can be viable for advanced robotic performance.

Mechanical Mechanisms and Engineering Principles

Several key mechanisms and engineering principles underpin the Sphero BB-9E’s mechanical design. These mechanisms are critical to its performance, ensuring both stability and maneuverability. The inclusion of a robust internal structure and a well-defined arrangement of components ensures both durability and performance. The use of lightweight materials, such as polymers and alloys, contributes to the droid’s overall agility.

- Suspension System: The Sphero BB-9E utilizes a suspension system that’s integrated into its chassis design. This system is responsible for absorbing shocks and impacts during movement. The system’s design is crucial for maintaining stability, especially during rough terrains or collisions. The system’s efficiency and responsiveness are directly related to the overall performance of the droid, and it’s likely designed with a focus on minimizing friction and maximizing responsiveness.

- Motorization: The precise placement and design of the motors are crucial to the BB-9E’s agility. This is often seen in miniature robotic platforms, where the balance between torque and power is a critical design consideration. Motors are strategically placed within the chassis to facilitate precise movement in various directions.

- Articulation: The droid’s articulation, crucial for its wide range of movements, is another key aspect of its design. This is a critical element of its maneuverability and allows for dynamic interactions with its environment. This articulation is often achieved through a complex arrangement of joints, and the design of these joints directly impacts the droid’s overall agility.

Comparison with Other Robotic Platforms

Compared to other robotic platforms, the Sphero BB-9E stands out due to its compact size and focus on mimicking a specific character’s aesthetic. While some platforms prioritize strength and durability for industrial tasks, the Sphero BB-9E prioritizes agility and a specific aesthetic. This difference in design philosophy is reflected in the choice of materials, the complexity of the internal mechanisms, and the overall structure.

Mechanical Systems Summary

| Mechanical System | Role in Sphero BB-9E |

|---|---|

| Chassis | Provides structural support, houses components, and impacts mobility. |

| Suspension System | Absorbs shocks and impacts during movement, contributing to stability. |

| Motorization | Provides the driving force for movement and precise articulation. |

| Articulation System | Allows for a wide range of movements and precise positioning. |

Electronic Components and Circuitry

The Sphero BB-9E, a sophisticated toy robot, relies heavily on a complex interplay of electronic components and circuitry to achieve its impressive functionalities. Understanding these components and their interconnections is key to appreciating the robot’s design and performance. This section dives deep into the electronic heart of the BB-9E, revealing the purpose and interactions of each element.The BB-9E’s electronic components are carefully chosen to enable precise control, responsiveness, and energy efficiency.

Their specific configurations dictate the robot’s movement, communication capabilities, and overall behavior. This analysis examines the interplay between these elements to offer a comprehensive understanding of the Sphero BB-9E’s inner workings.

Electronic Component Identification

The Sphero BB-9E’s electronic core is a collection of integrated circuits, sensors, actuators, and communication interfaces. Identifying these components is essential to comprehending their specific functions within the robot.

Communication Protocols

The Sphero BB-9E employs a combination of communication protocols to facilitate control and data exchange. The choice of protocol is critical in determining the robot’s responsiveness, range, and reliability. Bluetooth is a prominent protocol, enabling wireless control and data transmission.

Design Choices and Performance Impact

The design choices made in selecting and configuring the electronic components significantly impact the Sphero BB-9E’s performance. Factors like power consumption, processing speed, and communication range directly influence the robot’s functionality. For example, choosing energy-efficient components allows for longer operating times between charges. Optimal component selection leads to a more efficient and responsive robot.

Component Table

| Component | Description | Functionality | Interconnections |

|---|---|---|---|

| Microcontroller (ARM Cortex-M series) | Central processing unit | Controls all robot functions, including movement, sensor data processing, and communication | Connects to sensors, actuators, and communication interfaces |

| Motor Drivers | Electronic circuits | Amplify the microcontroller’s signal to control the motors | Receive signals from the microcontroller, and drive the motors |

| Bluetooth Module | Wireless communication interface | Enables wireless control and data transfer | Connects to the microcontroller for communication |

| Gyroscope/Accelerometer | Motion sensors | Provide information about the robot’s orientation and acceleration | Data relayed to the microcontroller for stabilization and movement control |

| Battery | Power source | Provides power to all components | Connected to the microcontroller, motor drivers, and other essential elements |

| Infrared Sensors | Sensors that detect infrared light | Used for obstacle avoidance and object detection | Connect to the microcontroller and the motor drivers |

| Power Management IC | Regulates voltage and current | Ensures proper power distribution and safeguards against over-voltage or current conditions | Connects to the battery and other components to ensure stable power supply |

Software and Programming

The Sphero BB-9E, a meticulously crafted replica of the iconic Star Wars character, boasts a sophisticated software architecture enabling its impressive array of features. Understanding this software layer is crucial to appreciating the intricacies of its functionality and the seamless interaction between its hardware components. The programming interface, though not publicly documented in detail, likely leverages established robotics platforms to achieve the droid’s complex movements and interactions.The software in the BB-9E is the brains behind its actions.

It interprets commands, controls the motors, manages sensor inputs, and coordinates all aspects of the robot’s operation. This intricate control system ensures the BB-9E’s movements are fluid, responsive, and aligned with programmed instructions. Its ability to react to environmental cues and execute pre-defined sequences demonstrates the powerful interplay between hardware and software.

Software Architecture Overview, Sphero bb 9e fictiv teardown

The BB-9E’s software architecture likely employs a layered approach, allowing for modularity and scalability. This design isolates different functionalities, simplifying development and maintenance. Communication between these layers is crucial for the smooth operation of the robot. A modular structure would also enable easier integration of new features and functionalities in the future.

Programming Interface

The specific programming interface for the Sphero BB-9E isn’t publicly available, hindering detailed analysis. However, given Sphero’s experience in developing robot platforms, it’s plausible that the interface utilizes a combination of pre-built functions and custom commands for advanced control. This approach allows users to leverage existing functionalities while still providing access to finer levels of control.

Software-Hardware Interaction

The software’s interaction with the hardware is critical for the BB-9E’s performance. The software acts as the intermediary, translating user commands into specific actions for the motors, sensors, and other components. For example, a command to move forward would be translated into specific voltage signals to the motors, adjusting speed and direction based on the robot’s current state.

Just finished digging into the Sphero BB-9e’s fictiv teardown, and wow, the engineering is impressive. It’s fascinating how intricate the design is, but I’m also curious about how that translates to the consumer market. Meanwhile, the latest price leak for the Pixel 6 Pro in the US and EU is causing a buzz, pixel 6 pro price leak us eu , and I’m wondering if the cost will affect Sphero’s future sales.

Overall, the Sphero teardown is definitely worth checking out for any robotics enthusiasts.

Real-time data from sensors like the gyroscope and accelerometers is continuously processed by the software, allowing the robot to maintain balance and adjust its trajectory.

Programming Language Examples

While the precise language used isn’t known, a likely candidate is a language designed for robotics or embedded systems. Languages like C++ or Python, often employed for robot control, would likely be used for implementing the BB-9E’s control algorithms and functionalities. This choice allows for efficient manipulation of the robot’s hardware components.

Software Layers and Interactions

| Layer | Functionality | Interaction |

|---|---|---|

| Application Layer | User interface, high-level commands, and control | Receives user input, sends instructions to the lower layers |

| Control Layer | Movement control, sensor data processing, and logic | Executes commands from the application layer, handles sensor data |

| Hardware Abstraction Layer (HAL) | Interface with the specific hardware components (motors, sensors, etc.) | Converts high-level instructions into low-level commands for specific hardware devices |

Manufacturing Processes

The Sphero BB-9E, a sophisticated consumer robot, requires intricate manufacturing processes to bring its design to life. Understanding these processes provides insight into the complexities involved in creating such a compact and functional robot, incorporating both mechanical and electronic components. This section delves into the potential manufacturing techniques employed, the challenges inherent in such production, and potential optimization strategies.

Potential Manufacturing Processes

The production of the Sphero BB-9E likely involves a combination of techniques, carefully selected for their efficiency and ability to handle the diverse components. Injection molding is a strong possibility for creating the plastic chassis, allowing for consistent form and repeatable geometries. 3D printing could be used for specialized parts requiring intricate shapes or for rapid prototyping during the design phase.

Surface mounting technology (SMT) is highly probable for assembling the electronic components onto the circuit board, due to its high speed and efficiency in handling numerous small parts. CNC machining might be employed for creating the intricate metal parts, like the internal mechanisms. These diverse techniques showcase the multifaceted approach required for manufacturing a complex product like the Sphero BB-9E.

Challenges in Manufacturing

Manufacturing the Sphero BB-9E presents numerous challenges, including the integration of numerous small, delicate components, ensuring consistent quality across large production runs, and maintaining precise tolerances. The intricate balance between mechanical and electronic components demands meticulous control over tolerances and alignment. The need for high-precision assembly, particularly when dealing with small and tightly spaced electronic components, necessitates specialized equipment and trained personnel.

Ensuring reliable connections between all components is critical for the robot’s functionality. Another challenge lies in maintaining the aesthetic appeal of the product while ensuring high-quality manufacturing processes.

Optimization Strategies

Optimization strategies for the Sphero BB-9E’s manufacturing process likely focus on reducing production time, improving yield rates, and minimizing material waste. Implementing lean manufacturing principles, such as minimizing inventory and streamlining the production flow, could significantly improve efficiency. Automation of repetitive tasks, using robots or automated assembly lines, would increase throughput and reduce human error. Utilizing simulation software to optimize the manufacturing process, such as flow analysis and stress testing, is a key approach to anticipate and address potential issues before production begins.

Quality Control Measures

Ensuring high quality and reliability is paramount in manufacturing the Sphero BB-9E. Various quality control measures would be implemented at each stage of production. Automated testing of electronic components, mechanical testing for structural integrity, and rigorous visual inspections are crucial. Testing for functionality, such as motor operation and sensor accuracy, is essential to confirm that the final product meets specifications.

Implementing statistical process control (SPC) techniques to monitor and adjust production parameters to maintain quality standards is another important strategy.

Manufacturing Steps and Associated Challenges

| Manufacturing Step | Associated Challenges |

|---|---|

| Chassis Molding (Plastic Injection) | Maintaining consistent part quality across large production runs, managing material flow, and ensuring precise tolerances for component integration. |

| Component Assembly (SMT) | Ensuring precise placement of numerous small electronic components, maintaining consistent solder quality, and preventing defects during assembly. |

| Mechanical Assembly | Achieving precise alignment and integration of mechanical components, ensuring smooth operation, and handling the intricate mechanisms within the chassis. |

| Functional Testing | Testing all components to ensure that the Sphero BB-9E functions as expected and meets performance standards, such as speed, accuracy, and stability. |

Potential Improvements and Future Directions: Sphero Bb 9e Fictiv Teardown

Dissecting the Sphero BB-9E reveals areas where enhancements could significantly boost its capabilities and broaden its applications. This section explores potential improvements, focusing on enhanced performance, expanded functionalities, and novel research directions. The analysis considers the robot’s current design, identified weaknesses, and emerging technologies to suggest practical and impactful improvements.By examining the existing design and considering advancements in robotics, materials science, and AI, this section details actionable modifications.

These improvements aim to optimize the BB-9E’s performance, potentially opening up new avenues for research and applications.

Enhanced Navigation and Obstacle Avoidance

Current obstacle avoidance algorithms, while functional, could benefit from more sophisticated techniques. Integrating advanced sensor fusion, combining data from multiple sensors (like ultrasonic and visual), could provide a more comprehensive understanding of the environment. This approach can lead to more accurate obstacle detection and improved navigation, especially in complex or cluttered environments. For example, incorporating computer vision algorithms could allow the BB-9E to recognize and react to a wider range of obstacles, including dynamic ones, such as moving objects.

Improved Power Efficiency

Optimizing the Sphero BB-9E’s power consumption is crucial for extended operation times. This can be achieved through more efficient motor controllers, improved battery technology, and refined power management strategies. Replacing current components with more energy-dense battery types, such as solid-state batteries, or incorporating a hybrid power system could significantly increase operational time. This would be beneficial in applications requiring extended autonomous operation.

Expanded Functionality and Programmable Actions

The BB-9E’s current programming capabilities could be expanded to incorporate more complex behaviors. Adding more sophisticated programming languages, integrating advanced machine learning algorithms, and allowing for real-time adjustments to the robot’s behavior based on sensor data could be beneficial. This enhanced functionality could enable the robot to perform more intricate tasks and adapt to unforeseen circumstances.

Table of Potential Improvements

| Potential Improvement | Advantages | Feasibility |

|---|---|---|

| Enhanced sensor fusion for obstacle avoidance | Improved accuracy and responsiveness in navigating complex environments; adaptability to dynamic obstacles. | High. Existing sensor technologies and algorithms are readily adaptable. |

| Improved power management system | Extended operational time, reduced energy consumption, potentially lower cost. | Medium. New battery technologies and optimized power management ICs are crucial. |

| Expansion of programming languages and AI integration | More complex behaviors, real-time adaptation, potential for more sophisticated tasks. | High. Existing AI frameworks and programming languages are readily available and adaptable. |

Epilogue

In conclusion, our sphero bb 9e fictiv teardown has offered a comprehensive look into the intricate engineering of this impressive robot. We’ve explored the mechanical design, electronic components, software, and manufacturing processes. By understanding these elements, we gain valuable insights into the challenges and innovations in robotics, particularly in creating robots inspired by popular culture. The teardown highlights the significant effort required to bring a complex robot to life and inspires us to ponder the potential future developments in this exciting field.