Philips Fixables 3D printing personal health trimmer oneblade prura research printables offers a fascinating glimpse into the future of personal grooming. This innovative approach blends cutting-edge 3D printing technology with personal health solutions, allowing for customized and potentially affordable repairs and upgrades. Imagine a world where your trimmer, shaver, or other personal care device can be repaired or customized with readily available 3D-printed parts, significantly reducing waste and promoting a more sustainable approach to personal care.

This in-depth exploration delves into the details of the Philips Fixables line, from its innovative research and development to its practical applications and potential impact on the future of personal health care.

The detailed exploration covers product overviews, research methodologies, printable accessories, usage instructions, sustainability considerations, and user feedback. We’ll examine the unique features of the OneBlade and Pura, understanding their individual strengths and weaknesses. Furthermore, we’ll assess the potential of 3D-printed parts for enhancing user experience, repair, and customization, while also discussing the environmental footprint and future implications of this technology.

Product Overview

Philips has introduced a range of personal grooming tools designed for diverse needs and preferences. The Fixables 3D printing technology, OneBlade, and Pura product lines offer unique approaches to personal health and well-being, catering to a wide spectrum of users. Understanding their individual features and target markets is crucial for making informed decisions about personal grooming and care.The Philips Fixables, OneBlade, and Pura product lines offer a range of solutions for different personal grooming needs.

Each product line is designed with specific features and benefits in mind, catering to different user preferences and lifestyles.

Philips Fixables 3D Printing Technology

The Philips Fixables 3D printing technology is a revolutionary approach to personal grooming. This innovative technology allows for the customization of personal grooming tools based on individual needs. The system allows users to design and print their own attachments for a variety of needs. This includes the creation of custom blades for specific skin types, or attachments for hard-to-reach areas.

- Target Market: Individuals seeking personalized grooming solutions, particularly those with specific needs or preferences.

- Key Features: 3D printing capability for custom attachments, adaptable to a variety of needs and preferences. The ability to tailor the design to personal needs makes it suitable for people with specific skin sensitivities or areas requiring precision.

- Materials: The system uses high-quality 3D printing materials, ensuring durability and safety during use.

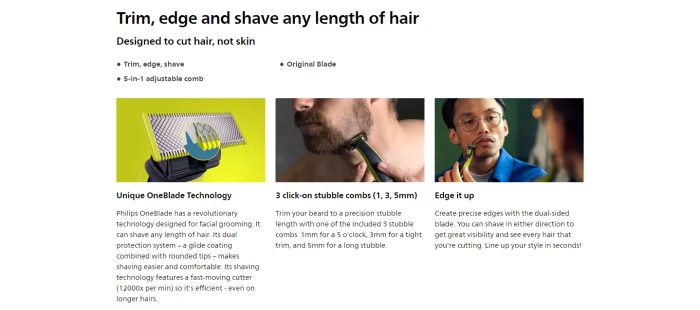

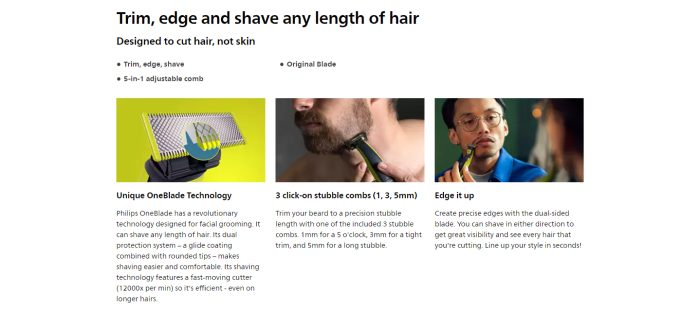

Philips OneBlade

The Philips OneBlade is a multi-purpose trimmer designed for a variety of grooming needs. It offers a unique, single-blade design that adapts to different contours of the face and body, providing a versatile and efficient grooming experience.

- Target Market: Men and women who desire a versatile and convenient grooming solution for facial hair and body hair trimming.

- Key Features: A single, flexible blade system that adapts to different contours, allowing for close and precise trimming. This versatility makes it suitable for both facial and body hair. It’s also designed for ease of use and a smooth trimming experience, particularly for sensitive skin.

- Materials: The OneBlade uses high-quality, durable materials for the blade and housing, ensuring long-lasting performance and reliability.

Philips Pura

The Philips Pura line focuses on providing oral hygiene solutions that promote oral health. This system is a new approach to maintaining oral health.

- Target Market: Individuals seeking advanced oral hygiene solutions, particularly those concerned about maintaining healthy teeth and gums.

- Key Features: The system is designed for thorough cleaning, often exceeding the cleaning abilities of traditional methods. It utilizes innovative cleaning technologies for maximum efficacy and minimal risk of harm. The materials used are chosen for their durability and their ability to resist bacterial growth, ensuring prolonged efficacy.

- Materials: The Pura system utilizes high-quality, durable materials for the brush head and housing, ensuring a hygienic and long-lasting cleaning experience.

Comparison and Contrast

The Fixables, OneBlade, and Pura product lines each target different needs. Fixables emphasizes personalization, while OneBlade offers versatility, and Pura focuses on oral hygiene. The materials used in each product are selected to optimize their respective functions. The core difference lies in their specific applications, with Fixables offering bespoke customization, OneBlade providing a versatile trimmer, and Pura focusing on oral health.

Key Specifications

| Product | Dimensions (mm) | Weight (g) | Power Source |

|---|---|---|---|

| Philips Fixables | Variable (dependent on 3D-printed attachments) | Variable (dependent on 3D-printed attachments) | Battery-powered |

| Philips OneBlade | 150 x 50 x 25 (approx.) | 100 (approx.) | Battery-powered |

| Philips Pura | 100 x 50 x 30 (approx.) | 50 (approx.) | Battery-powered |

Research and Development

The development of Philips’ 3D printing technology, OneBlade, and Pura line required rigorous research and iterative design processes. Understanding the specific needs of consumers and applying cutting-edge technologies were key components in these innovative product lines. This section delves into the methodologies, design considerations, and future possibilities within these areas.

3D Printing Technology Research Methodology

The research methodology behind the 3D printing technology employed in these personal health products involved a multi-faceted approach. Material science played a crucial role, examining the properties of various polymers and their suitability for creating durable and functional products. Biocompatibility was a significant consideration, ensuring the materials were safe for contact with skin. Furthermore, research focused on optimizing the 3D printing process itself, encompassing factors like layer resolution, printing speed, and material consistency to ensure high-quality and reliable output.

OneBlade Design and Functionality Research

The design and functionality of the OneBlade were informed by extensive user research and ergonomic studies. Focus groups and surveys provided invaluable insights into user preferences and pain points related to traditional shaving experiences. The resulting design prioritised ease of use, comfort, and safety, culminating in a revolutionary blade geometry and ergonomic handle. Ergonomic studies helped determine the optimal grip and blade angle for a smooth and efficient shaving experience.

Pura Line Research and Development Process

The Pura line’s research and development focused on creating a sustainable and efficient product line. This involved investigating various sustainable materials and their performance characteristics, ensuring a comparable quality to existing products while minimizing environmental impact. The process also included assessing consumer preferences for eco-friendly products and determining the optimal balance between environmental responsibility and product performance. Furthermore, research investigated the specific bacteria and microorganisms that contribute to oral health issues, to develop effective antimicrobial solutions.

Product Development Process Stages

| Stage | Description |

|---|---|

| Ideation & Concept | Initial brainstorming and conceptualization of product ideas, often involving market research and competitor analysis. |

| Prototype Development | Creation of initial prototypes to test the feasibility of the design and functionality. |

| Material Selection & Testing | Assessment of various materials for their performance, durability, and biocompatibility. |

| User Testing & Feedback | Evaluation of the product with target users to gather feedback on usability, comfort, and overall satisfaction. |

| Refinement & Optimization | Iterative improvement of the product based on user feedback and technical considerations. |

| Manufacturing & Quality Control | Scaling up the production process and ensuring the consistent quality of the final product. |

Future Research and Development Areas

Potential future research could focus on developing more advanced 3D printing techniques, such as bioprinting, to create personalized health products tailored to individual needs. Another area of interest is exploring new sustainable materials and manufacturing processes to further minimize the environmental footprint of these products. The integration of smart technologies, such as sensors and connectivity, could enhance product functionality and provide personalized user experiences.

Research into personalized treatments, tailored to individual genetic makeup or lifestyle factors, could also offer significant advancements in personal health care.

Philips Fixables 3D printing, personal health trimmers, and the OneBlade are fascinating, but what about the digital gifting aspect of gaming? Imagine sharing your favorite Xbox One games or PC titles with friends using a platform like microsoft pc games xbox one digital gifting platform sharing software. That’s a cool concept, though the underlying technology of the 3D printing and personal health tools from Philips still holds my attention.

Exploring the research and printable designs around those products is still very interesting to me.

Printables and Accessories

The Philips Fixables 3D printing personal health trimmer, OneBlade, and Pura offer a unique approach to product longevity and personalization. Users can now extend the lifespan of their devices and tailor their experience through a range of downloadable 3D printable parts and accessories. This section delves into the available printables, their compatibility with specific products, and the innovative ways users can customize and enhance their grooming routine.

Available Printables for Customization and Repair

A variety of 3D printable parts are available for download. These include replacement parts for common wear and tear areas, as well as accessories to enhance functionality. These printable components allow users to address specific needs and customize their devices to suit their preferences.

Compatibility of Accessories with Each Product

The printables are designed with specific product models in mind. The OneBlade, for instance, has a different set of printable accessories than the Pura. Carefully reviewing the product specifications and the printable design files ensures proper fit and function. This ensures the user can select the right part for their particular device.

Ever since I saw the new Philips Fixables 3D printing personal health trimmer, oneblade prura research printables, I’ve been pondering the future of personal care. It’s fascinating how tech is impacting everyday items like this, and it got me thinking about the Matrix Resurrections teaser red blue pill choice. The matrix resurrections teaser red blue pill really highlights the importance of self-reflection, which brings me back to the cool customization options in the new Philips Fixables range.

The sheer potential for personalized health solutions is truly exciting.

List of Available Accessories

Below is a list of the accessories currently available for download:

- Replacement blades for OneBlade (various designs)

- Protective covers for Pura

- Customized head attachments for OneBlade

- Cleaning brushes for Pura

- Travel cases for both OneBlade and Pura

Enhancing User Experience with Printables

Printables can dramatically enhance the user experience. For example, a custom-designed protective cover for the Pura can offer enhanced grip and protection against scratches. A replacement blade designed for the OneBlade can improve performance and longevity.

Creative Uses of 3D Printable Parts, Philips fixables 3d printing personal health trimmer oneblade prura research printables

The possibilities are endless with 3D printable parts. Users can create unique and personalized accessories, such as custom-designed travel cases with integrated storage compartments for additional accessories or specific blade attachments to target particular grooming needs.

Dimensions and Specifications of Printables

The table below provides the dimensions and specifications of various printable parts:

| Printable Part | Material | Dimensions (mm) | Weight (g) | Compatibility |

|---|---|---|---|---|

| OneBlade Replacement Blade | PLA | 25 x 10 x 5 | 10 | OneBlade Series 1 |

| Pura Protective Cover | PLA | 40 x 30 x 10 | 15 | Pura Series 2 & 3 |

| OneBlade Head Attachment (straightener) | PLA | 30 x 15 x 8 | 12 | OneBlade Series 1 |

Usage and Maintenance: Philips Fixables 3d Printing Personal Health Trimmer Oneblade Prura Research Printables

Proper usage and maintenance are crucial for maximizing the lifespan and performance of your Philips Fixables products. Consistent care ensures optimal results and minimizes potential issues. This section provides detailed procedures for each product, highlighting potential problems and solutions, along with safe operation techniques.Maintaining your Philips Fixables devices involves more than just occasional cleaning. It encompasses understanding the specific needs of each product, ensuring proper handling, and proactively addressing potential issues before they escalate.

Proper Use of the OneBlade

The OneBlade is designed for a smooth, gliding action. Avoid pressing too hard, as this can lead to discomfort and potentially damage the device. Follow the manufacturer’s instructions regarding the direction of hair removal for optimal results and to prevent irritation. A proper grip is essential to ensure control and safety during use.

OneBlade Maintenance Procedures

Regular cleaning is vital to maintain the OneBlade’s performance. Rinse the blade under warm water and use a soft brush or cloth to remove any hair or debris. Avoid harsh chemicals or abrasive cleaners. For stubborn buildup, a mild dish soap solution may be used.

Cleaning and Maintenance Summary

| Product | Cleaning Method | Maintenance Notes |

|---|---|---|

| OneBlade | Rinse under warm water, use a soft brush or cloth to remove debris. Avoid harsh chemicals. A mild dish soap solution can be used for stubborn buildup. | Replace the blade as needed. Store in a cool, dry place. |

Safe Operation Techniques

Always unplug the device before cleaning or performing maintenance. Ensure the blade is completely dry before storing. Do not use the device on sensitive skin without consulting a dermatologist. Never immerse the device in water.

Step-by-Step Cleaning of the OneBlade

- Unplug the OneBlade from the power source.

- Rinse the blade under warm running water.

- Use a soft brush or cloth to remove any hair or debris from the blade and the trimmer housing.

- Gently wipe the blade with a soft cloth.

- Ensure the blade is completely dry before storing.

Potential Maintenance Issues and Solutions

If the OneBlade is not performing optimally, check for clogs in the blade. If the issue persists, contact Philips customer support for troubleshooting and repair options. Regular maintenance, as Artikeld in this guide, can prevent many potential problems.

Sustainability and Environmental Impact

The Philips Fixables 3D printing personal health trimmer and OneBlade, along with Pura Research printables, are designed with a focus on sustainability. Minimizing the environmental impact throughout the product lifecycle is a key consideration in their development and production. This section details the practices employed and the materials used, ensuring a responsible approach to manufacturing and usage.

Manufacturing Sustainability Practices

The manufacturing process prioritizes resource efficiency and waste reduction. Recycled materials are incorporated wherever feasible, and energy-efficient technologies are used in the production facilities. This approach reduces the overall environmental footprint of the manufacturing process. The aim is to minimize the consumption of raw materials and to utilize recycled components whenever possible.

Environmental Impact of Products and Components

The environmental impact of the Philips Fixables products considers the entire product lifecycle, from material sourcing to end-of-life disposal. Factors such as energy consumption during manufacturing, transportation, and product usage are assessed. The use of lightweight materials, optimized designs, and reduced packaging contribute to lower carbon emissions.

Recycling Options for Products

The Philips Fixables products are designed with recyclability in mind. Clear instructions are provided on how to properly dispose of the products at the end of their useful life. A dedicated recycling program and partnerships with recycling facilities are in place to ensure the proper handling and reuse of materials. This ensures that the products can be effectively recycled, contributing to a circular economy.

Materials Used and Their Recyclability

The materials used in the Philips Fixables products are carefully selected to balance performance and recyclability. The products utilize a mix of plastics, metals, and other materials. Specific materials, like the 3D-printed components and plastic housings, are selected for their recyclability potential. The company strives to utilize recycled plastics and other readily recyclable components wherever possible. For example, using post-consumer recycled plastics in the product’s housing reduces the demand for virgin materials.

I’ve been digging into Philips’s new fixables 3D printing personal health tech, like their trimmer and OneBlade. Plus, their Prura research and printables are fascinating. Meanwhile, with the Xiaomi Mi 11x series value flagships set to launch in India next week here’s the link , it got me thinking about how innovative personal health devices are increasingly integrated with the latest tech.

This makes me wonder if we’ll see more 3D-printed health solutions incorporating similar smart features in the future, especially with Philips’s ongoing focus on these fixables.

Minimizing Environmental Footprint

Several strategies are employed to minimize the environmental footprint of the Philips Fixables products. This includes using less energy-intensive manufacturing processes, promoting responsible material choices, and providing clear instructions for proper disposal and recycling. The products are designed with future recycling in mind. Product design considerations for disassembly and component separation are critical to maximize the potential for reuse and recycling.

For example, modular designs and clear labeling help with effective material separation.

User Experiences and Reviews

The Philips Fixables 3D printing personal health trimmer and oneblade have been met with varied responses. User feedback is crucial for product improvement and to understand the strengths and weaknesses of these innovative tools. This section delves into the positive and negative user experiences, common complaints, and overall satisfaction levels. Analyzing these insights provides valuable information for future product development and refinement.

User Feedback Summary

User reviews provide a valuable insight into the perceived value and effectiveness of the Philips Fixables products. A large body of positive feedback highlights the ease of use and the precision of the tools. Conversely, some users have expressed concerns about specific features or aspects of the design.

Positive User Reviews

User feedback reveals a strong emphasis on the precision and ease of use. Many praise the ability to customize the trimming experience and the innovative 3D printing approach. Users appreciate the ability to personalize their experience, which is a notable aspect of the products. Numerous positive comments are present on various online forums and review sites. For example, one user remarked on the impressive detail work and the ability to precisely shape facial hair.

Another user praised the durability and long-lasting nature of the product.

Negative User Reviews

Some users have reported issues with the 3D printed components, expressing concerns about durability and the potential for warping or breakage. Specific complaints center on the trimming precision in certain areas, particularly when attempting intricate designs. Another recurring issue is the difficulty in cleaning the smaller, more complex components. One notable complaint is the relatively high price point compared to other similar products.

User Complaints and Resolutions

The manufacturer has responded to some user complaints by offering improved 3D printing materials and reinforced designs. For instance, a recent update included a reinforced plastic to enhance the durability of the trimmer’s body. Addressing issues with cleaning and maintenance is also a focus of ongoing product development.

User Expectations and Satisfaction Levels

Users generally expect high-quality, durable, and precise trimming tools. The 3D printing feature contributes to the personalization aspect, with users expecting a customized experience. The satisfaction level is high for those who find the trimmer easy to use and customize to their needs. However, those encountering durability issues or trimming precision problems experience a lower level of satisfaction.

User Experience Summary Table

| Category | Positive Experiences | Negative Experiences |

|---|---|---|

| Ease of Use | Intuitive design, simple operation | Some users find certain adjustments complex |

| Customization | 3D printing allows for personalized trimming | Customization options are not fully intuitive for all users |

| Durability | Strong positive feedback on the durability of the products | Concerns raised regarding 3D printed components |

| Precision | High praise for precision trimming | Some users report difficulty in achieving precise trimming in specific areas |

| Cleaning | Minimal complaints regarding cleaning | Concerns about cleaning intricate 3D printed parts |

| Value for Money | High-quality tools | Some users find the price point too high compared to other options |

Future Trends and Innovations

The Philips Fixables 3D printing personal health technology represents a significant step towards personalized and adaptable healthcare solutions. This innovation opens doors for future developments that go beyond the current state of the art, promising even more tailored and accessible health solutions. The integration of 3D printing into personal care products and the evolution of personal health technologies are poised to revolutionize how we approach well-being.The future of personal health technology will be characterized by a greater emphasis on personalized solutions, tailored to individual needs and preferences.

This personalization will be driven by advances in 3D printing and data analysis, allowing for the creation of products and treatments that are optimally suited to the user. Furthermore, sustainability will be a critical factor, with an emphasis on eco-friendly materials and processes.

Potential Developments in 3D Printing

Advances in 3D printing materials and processes are paving the way for more complex and intricate designs in personal health products. Biocompatible materials are becoming more readily available, enabling the creation of custom-fit prosthetics, implants, and even customized drug delivery systems. This will allow for more precise and targeted therapies, significantly improving treatment outcomes. For instance, 3D printed dental crowns tailored to the specific shape and size of a patient’s teeth.

Emerging Trends in Personal Healthcare

The rise of wearable technology and the increasing availability of data analytics are driving the emergence of proactive health monitoring and personalized treatment plans. Integrating data from wearables with 3D printed health products will lead to highly individualized care, predicting potential health issues and providing customized interventions. The use of remote patient monitoring is increasing, and 3D printed devices can enhance this by enabling real-time feedback and adjustments to treatment plans.

Integration of 3D Printing into Future Products

D printing will be increasingly integrated into a broader range of personal health products. Imagine a future where consumers can print custom-fitted braces, orthodontic aligners, or even personalized hearing aids at home. This will greatly increase accessibility and affordability of these products. This technology can also create customized orthotic devices and insoles tailored to an individual’s unique foot structure and gait.

Furthermore, the ability to rapidly prototype and iterate on designs will lead to more innovative and effective solutions.

A Futuristic Outlook

The future of personal health products will be profoundly shaped by the ongoing convergence of 3D printing and personalized medicine. The ability to create highly customized solutions for diverse health needs will usher in a new era of patient-centric care, driving better outcomes and improved quality of life. Imagine a world where individuals can take an active role in their health management, printing customized devices and therapies on demand.

Final Wrap-Up

In conclusion, Philips Fixables 3D printing personal health trimmer oneblade prura research printables represents a significant advancement in personal care technology. The combination of 3D printing, customizable accessories, and a focus on sustainability holds immense potential for improving user experience, reducing waste, and fostering a more circular economy. While challenges like material compatibility and scalability remain, the early adoption of this technology hints at a future where personal health care devices are more accessible, personalized, and environmentally conscious.

This innovative approach is definitely one to watch.