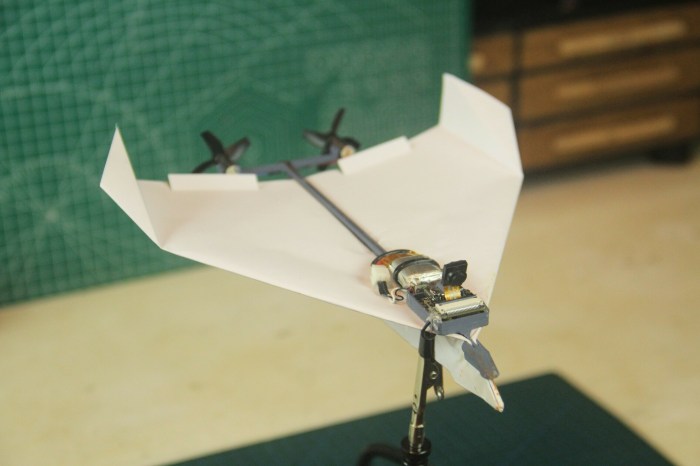

Paper airplane FPV control opens a fascinating world of miniature flight. Imagine remotely piloting a meticulously crafted paper airplane, using a first-person view (FPV) system. This innovative approach blends the timeless art of paper airplane design with cutting-edge technology, exploring the fundamental principles of flight and the intricate engineering involved in creating a fully controlled miniature aircraft. We’ll delve into the design considerations, the essential components, and the complex control systems needed to make this dream a reality.

From the historical evolution of paper airplane design to the latest advancements in FPV technology, this exploration will cover the entire spectrum of this exciting project. We’ll examine the various materials, control surfaces, and sensors that are crucial for creating a responsive and precise flying machine. The project will be further illustrated with practical examples and detailed tables.

Introduction to Paper Airplane FPV Control

Paper airplanes, a timeless pastime, are now poised for a futuristic leap with the integration of First-Person View (FPV) technology. FPV, in essence, provides a real-time, first-person perspective of the airplane’s flight path, allowing for precise control and refined maneuvers. This technology, usually associated with drones and racing vehicles, finds an intriguing application in the seemingly simple world of paper airplanes.The history of paper airplane design is rich and diverse, demonstrating human ingenuity in manipulating aerodynamic forces.

From basic designs optimized for distance to more complex configurations focusing on controlled turns and loops, the evolution of paper airplane design mirrors the development of flight mechanics and control systems. The integration of FPV technology represents a significant step forward in this evolution, allowing for unprecedented levels of precision and control.

Fundamental Principles of Flight Mechanics

Paper airplane flight is governed by fundamental aerodynamic principles. The primary forces influencing flight are lift, drag, thrust, and weight. Lift is generated by the interaction of the airflow with the wing’s shape, creating an upward force that opposes gravity. Drag, acting in the opposite direction of motion, resists the forward movement. Thrust, usually provided by the initial launch, propels the airplane forward.

The balance of these forces dictates the airplane’s trajectory. Control surfaces, such as the wings and tail, manipulate these forces, allowing for precise control of the airplane’s pitch, yaw, and roll. Understanding these forces and their interplay is crucial for effective FPV control.

Lift = 1/2

- ρ

- V2

- S

- CL

, where ρ is air density, V is velocity, S is wing area, and CL is lift coefficient.

Different Paper Airplane Designs and FPV Control Potential

Different paper airplane designs offer varying degrees of maneuverability and potential for FPV control. The classic dart design, with its simple, streamlined shape, excels at distance but lacks the maneuverability required for intricate FPV-driven maneuvers. Conversely, designs incorporating complex wing configurations and control surfaces, such as delta wings or swept-wing designs, offer greater potential for precise control. This control is dependent on the interplay of aerodynamic forces and the responsiveness of the control surfaces.

The success of FPV control will rely heavily on the design’s adaptability to real-time feedback and input.

Paper Airplane Designs for FPV Control

| Design | Control Mechanism | Flight Characteristics |

|---|---|---|

| Dart | Minimal control surfaces; relies on initial launch angle | High speed, limited maneuverability |

| Delta Wing | Highly swept wings for enhanced maneuverability; potentially adjustable control surfaces | High maneuverability, potentially responsive to FPV input |

| Symmetrical Biplane | Multiple wings; potential for independent control surfaces | Increased lift, potentially better control, but more complex to manufacture |

These examples highlight the diverse range of possibilities. The design’s ability to respond to real-time adjustments from FPV input is paramount for effective control. The potential of FPV control varies significantly across these designs, with some offering greater adaptability and responsiveness than others.

Components and Design Considerations

Building a paper airplane for FPV control requires careful consideration of its components and design. The fundamental elements are similar to a standard paper airplane, but precise construction and materials selection are crucial for achieving stable flight and reliable sensor/actuator integration. Successful FPV implementation depends on the interplay of aerodynamic properties, material strength, and control mechanisms.The design must balance the need for lightweight construction to maintain flight speed with the requirement for sufficient strength to withstand the stresses of flight and actuator movements.

Optimal material choices and control surface design are essential to achieving precise and predictable flight paths, which are critical for accurate FPV data acquisition and effective control.

Essential Components

The core components necessary for FPV control on a paper airplane include the airplane structure itself, sensors for feedback, actuators for control, and a power source (if required). A lightweight frame, meticulously crafted from strong yet flexible materials, forms the foundation. Sensors, such as accelerometers, gyroscopes, and possibly magnetometers, are attached for real-time data acquisition regarding the airplane’s orientation and position.

These signals provide the feedback needed for the flight controller to adjust the actuators. Actuators, such as small servo motors or other appropriate mechanisms, translate control signals into physical adjustments of the control surfaces, enabling precise adjustments to flight paths.

Materials for Construction, Paper airplane fpv control

The choice of material significantly impacts the flight performance of the paper airplane. Lightweight materials like thin, strong paper, balsa wood, or even specialized composites can be used. The selection should balance weight with structural integrity to achieve controlled flight. Materials with higher tensile strength and lower weight contribute to a more responsive and stable flight path.

Material Comparison Table

| Material | Weight | Strength | Aerodynamic Properties |

|---|---|---|---|

| Thin, strong paper (e.g., printer paper, craft paper) | Low | Moderate | Good lift-to-drag ratio, but susceptible to tearing |

| Balsa wood (thin strips) | Low | High | Excellent strength-to-weight ratio, good aerodynamic properties, but can be difficult to work with |

| Lightweight composites (e.g., carbon fiber paper) | Very low | Very high | Excellent aerodynamic properties, high strength-to-weight ratio, more expensive |

Control Surface Design

Effective control surfaces are essential for directing the paper airplane’s flight. Ailerons, elevators, and rudders are common control surfaces, and their design directly affects the responsiveness and precision of the airplane. The shape, size, and placement of these surfaces should be carefully considered to achieve the desired flight characteristics. The degree of controllability achieved through adjustments of these surfaces affects the overall control response of the aircraft.

Proper sizing and arrangement of control surfaces are vital for precise maneuvering.

Ever thought about controlling a paper airplane with FPV? It’s a surprisingly complex hobby, and the latest news about YouTube TV expanding into 10 new markets here might just give you a new perspective on the potential of remote control. Regardless of global streaming services, building and piloting these tiny aircraft with FPV remains a captivating pursuit.

Sensor and Actuator Attachment Methods

Attaching sensors and actuators requires precise techniques to maintain the airplane’s structural integrity and flight characteristics. Small, lightweight adhesive tape, specialized mounting clips, or 3D-printed components can be employed. Careful consideration must be given to the mounting points to minimize the added weight and ensure stability during flight. The attachment points need to be strong enough to support the actuators without compromising the integrity of the airplane’s structure.

Using appropriate mounting techniques helps prevent sensor/actuator failure and maintains the airplane’s structural integrity.

Control Systems and Implementation

Crafting a paper airplane capable of FPV control necessitates a robust control system. This system must precisely interpret the signals from the camera and translate them into adjustments to the airplane’s orientation and movement. The ideal control system will be both effective and manageable, considering the limitations of the platform. The choice of control system is crucial in determining the success of the FPV project.Implementing a control system for a paper airplane requires careful consideration of the trade-offs between complexity, cost, and performance.

Ever wondered how you could control a paper airplane with FPV? It’s surprisingly complex, requiring precise calculations and a stable platform. While exploring the high-octane electric performance specs of the Mercedes Benz AMG EQS, I found the intricate details of the mercedes benz amg eqs electric performance specs iaa fascinating, but I quickly returned to the meticulous calculations needed to make my paper airplane FPV work.

Ultimately, both the electric car and the paper plane control systems share a focus on precise engineering, and that’s what makes both so cool.

A simple system might offer basic control, but a more intricate system may yield greater precision and responsiveness. Finding the optimal balance is essential to achieving the desired level of control and maneuverability.

Overview of Control Systems

Various control systems are applicable to paper airplane FPV, ranging from basic PID controllers to more complex systems incorporating machine learning algorithms. Choosing the right system depends heavily on the intended performance requirements and the resources available.

Comparison of Control Systems

A crucial aspect of system selection is comparing the advantages and disadvantages of different control approaches. This comparison considers factors like complexity, cost, and expected performance.

- Proportional-Integral-Derivative (PID) Controllers: PID controllers are widely used for their simplicity and effectiveness in many control applications. They are relatively inexpensive to implement and offer good performance in many cases. However, their performance might not be optimal for complex maneuvers or in environments with significant disturbances.

- Fuzzy Logic Controllers: Fuzzy logic controllers excel in situations where precise mathematical models are difficult to establish. They are particularly suited for tasks where human intuition and experience play a significant role. While fuzzy logic can lead to robust control in some cases, they might prove more complex to implement than PID controllers.

- Machine Learning-based Controllers: Machine learning algorithms can adapt to various conditions and learn from experience. This allows for the development of highly sophisticated control systems capable of handling intricate maneuvers. However, the complexity and computational requirements of these systems are typically higher compared to the other options.

Calibration and Adjustment Procedures

Calibration and adjustment are critical to achieving optimal performance from any control system. This involves fine-tuning the parameters of the chosen controller to match the characteristics of the paper airplane.

- PID Controller Tuning: PID controller parameters (proportional gain, integral gain, and derivative gain) need careful tuning to balance responsiveness and stability. This is typically done through trial and error, or through systematic methods like Ziegler-Nichols tuning.

- Fuzzy Logic Controller Rule Adjustment: Adjusting the rules and membership functions in a fuzzy logic controller can refine the system’s behavior to match the desired response.

- Machine Learning Model Training: Training machine learning models for FPV control involves providing a sufficient amount of data representing the desired airplane behavior. The model will learn the relationships between input signals (camera feed) and the desired outputs (control adjustments).

Integration into Paper Airplane Design

Integrating the control system into the paper airplane’s design involves careful consideration of the system’s size, weight, and power requirements. This often necessitates innovative solutions to accommodate these components without compromising the airplane’s aerodynamic properties.

Control Algorithms

Different algorithms govern the control system’s actions. The algorithm determines how the system interprets input from the camera feed and translates it into control signals.

- Orientation Control: Algorithms for controlling the paper airplane’s orientation typically involve using the camera’s data to determine the airplane’s position and orientation relative to the target and then adjusting the control surfaces accordingly.

- Movement Control: Algorithms for controlling the airplane’s movement often rely on feedback loops that use the camera feed to adjust the thrust or direction of the airplane’s movement.

Design and Implementation Steps

This table Artikels the key steps involved in designing and implementing the FPV control system for a paper airplane.

| Step | Description |

|---|---|

| 1 | Define the desired performance criteria. |

| 2 | Select the appropriate control system. |

| 3 | Design the control algorithm. |

| 4 | Calibrate and adjust the control system. |

| 5 | Integrate the control system into the airplane’s design. |

| 6 | Test and refine the control system. |

Software and Programming

Crafting the software that controls our paper airplane’s FPV journey is a crucial step. This involves selecting appropriate tools, choosing suitable programming languages, and meticulously writing and debugging code to ensure precise and reliable flight. The software acts as the brain of the system, translating sensor inputs into actionable commands for the actuators. Without robust software, the FPV system will be unable to perform its intended function.

Ever wondered about paper airplane FPV control? It’s a fascinating area, but lately, regulators are looking at the inflection and Microsoft deal, which could impact future developments in this space. This might affect how we see FPV technology in paper airplanes, potentially leading to new restrictions or even exciting new possibilities. Hopefully, the future of paper airplane FPV control remains bright!

Software Tools for Programming

Essential software tools for programming and controlling the FPV system include integrated development environments (IDEs), compilers, and debuggers. IDEs provide a structured environment for writing, editing, compiling, and debugging code. Compilers translate the code written in a high-level language into machine-executable instructions. Debuggers help identify and fix errors in the code. Popular choices include Arduino IDE, which is widely used for microcontroller programming, or Python with libraries like Pygame for graphical interfaces and data analysis.

The selection of the tools depends on the chosen programming language and the specific functionalities required for the project.

Programming Languages for FPV Control

Several programming languages are suitable for controlling the paper airplane’s flight. The choice depends on factors such as the complexity of the control algorithms, the processing power available on the microcontroller, and the programmer’s familiarity with the language.

- Python is a popular choice due to its readability and extensive libraries. Its versatility makes it suitable for various tasks, including data analysis, sensor data processing, and control algorithm implementation.

- C++ offers high performance and control over hardware, making it ideal for systems demanding real-time responsiveness. Its low-level access allows for direct interaction with hardware components, enabling intricate control mechanisms.

- Arduino’s programming language, a dialect of C++, is particularly well-suited for microcontrollers. Its concise syntax and integrated development environment simplify the programming process for these types of embedded systems.

Writing and Debugging FPV Control Code

The process of writing and debugging code for the control system involves several steps. First, the design of the control algorithms must be translated into code. Then, the code must be thoroughly tested and debugged to ensure accurate functionality. This often involves simulating the flight scenario and meticulously examining the sensor data and control outputs. Debugging tools like print statements, breakpoints, and logging facilities are essential for isolating and resolving errors.

Sensor Types for Feedback

Different types of sensors can provide feedback to the control system, enabling it to adjust the paper airplane’s flight path. The choice of sensor depends on the specific requirements of the control algorithm and the constraints of the project.

- Accelerometers measure acceleration forces, which can be used to detect changes in the airplane’s orientation and movement.

- Gyroscopes measure angular velocity, allowing the system to determine the airplane’s rotational motion.

- GPS modules provide location data, facilitating long-distance or obstacle avoidance maneuvers.

- Ultrasonic sensors measure distance to objects in the environment, essential for obstacle avoidance and landing.

Data Acquisition from Sensors

Data acquisition from the sensors involves reading sensor values and processing them in real-time. The data is then used to adjust the control outputs. The rate at which the data is read and processed is critical for real-time control. A real-time operating system (RTOS) can often help with this. Software libraries for the chosen sensor types can streamline the data acquisition process.

| Language | Suitability |

|---|---|

| Python | Excellent for initial prototyping and data analysis, but may not be the fastest for real-time control. |

| C++ | Excellent performance, suitable for demanding real-time control applications. |

| Arduino (C++) | Ideal for microcontroller-based systems; strong integration with hardware. |

Practical Application and Testing

Putting your FPV-controlled paper airplane through its paces is crucial for refining the control system and ensuring its reliability. This phase involves meticulously testing various scenarios, analyzing performance, and systematically addressing any issues that arise. A well-defined testing procedure is essential for accurate evaluation and improvement.Thorough testing is vital to identify any flaws or inefficiencies in the FPV control system before it’s deployed in more complex or real-world applications.

Precise evaluation and methodical troubleshooting help to ensure a stable and responsive control system for the paper airplane.

Testing Methods and Scenarios

Effective testing requires a structured approach to evaluate the system’s performance under diverse conditions. This includes simulating different flight paths, examining responsiveness to control inputs, and assessing the system’s stability in various environments. Testing procedures must account for unexpected events or external factors that might affect the airplane’s flight.

- Static Tests: Initial testing involves static positioning of the airplane and examining the response to control inputs without movement. This allows for precise calibration and assessment of the control system’s accuracy at rest. Static tests should be repeated under various conditions of light and wind to observe any effects on the control system.

- Dynamic Tests: Dynamic tests assess the airplane’s performance during actual flight. This includes testing various flight patterns such as straight lines, turns, loops, and spirals. These tests help to evaluate the control system’s responsiveness and stability under varying conditions of speed and altitude. Monitoring the flight path and control inputs during these tests is essential.

- Environmental Tests: Testing in diverse environmental conditions is vital. These tests evaluate how the system performs in varying wind speeds and directions, lighting conditions, and temperature fluctuations. This step allows for the identification of any unexpected responses due to environmental factors.

- Stress Tests: Stress tests push the control system to its limits to identify potential weaknesses. These tests can include rapid, unexpected control inputs, sudden changes in altitude or speed, and extreme maneuvering. This helps in determining the system’s robustness and stability under challenging conditions.

Troubleshooting the Control System

Troubleshooting issues in the FPV-controlled paper airplane requires a systematic approach. Begin by identifying the specific problem, noting the conditions under which it occurred, and then isolating the source of the error.

- Identifying the Problem: Careful observation of the airplane’s flight behavior and comparison with expected performance are essential. Record any inconsistencies or unexpected responses in the flight path.

- Isolating the Cause: Review the components of the system, checking for malfunctions in the transmitter, receiver, or flight controller. This could involve checking for loose connections, faulty sensors, or errors in the software programming.

- Implementing Solutions: Once the source of the problem is identified, appropriate solutions can be implemented. This may involve re-calibrating the system, adjusting the software settings, or replacing faulty components.

Testing Results Tracking

A well-structured table helps to organize and analyze testing results. This allows for easy identification of trends, patterns, and areas for improvement.

| Test Case | Description | Results | Observations |

|---|---|---|---|

| Static Calibration | Testing response to control inputs in a stationary position | Control inputs consistently resulted in expected movements. | No drift or unexpected behavior observed. |

| Straight Line Flight | Testing the airplane’s ability to maintain a straight line flight | Airplane maintained a straight line with minimal deviation. | Slight deviation observed at higher speeds, requiring further adjustment. |

| Wind Tunnel Test | Testing in varying wind conditions | Control system maintained stability in moderate winds, but lost control in high winds. | Control system needs stronger stabilization for high wind conditions. |

Safety Procedures for Testing

Safety is paramount during testing. These procedures aim to prevent accidents and minimize risks associated with the project.

- Designated Test Area: Conduct tests in a designated area with minimal obstructions to ensure clear visibility and prevent damage to property.

- Appropriate Supervision: Ensure proper supervision during all testing phases, especially when conducting dynamic or stress tests.

- Emergency Procedures: Have a clear plan in place for handling emergencies, including a method for safely recovering the airplane if it malfunctions or loses control.

Future Directions and Possibilities

The realm of paper airplane FPV control, while nascent, presents exciting opportunities for improvement and innovation. Beyond basic flight control, future developments could significantly enhance the performance and capabilities of these miniature aerial vehicles, potentially opening avenues for new applications. This exploration delves into potential enhancements, innovative ideas, future research directions, and broader applications.

Potential Improvements to the FPV Control System

Refinement of the control algorithms is crucial for achieving more stable and predictable flight trajectories. Current systems may struggle with unpredictable wind gusts or minor structural variations in the paper airplane’s design. Advanced algorithms, potentially incorporating machine learning techniques, could analyze real-time flight data and adjust control inputs dynamically, leading to more robust and reliable flight. This enhancement would significantly contribute to the overall flight performance and reduce variability in the control response.

Innovative Ideas for Enhancing Flight Performance

One innovative idea involves incorporating a miniature, lightweight, and low-power sensor system into the paper airplane. This system could measure factors like airspeed, altitude, and yaw rate, providing more comprehensive flight data. This data could then be used to enhance control algorithms, enabling more complex maneuvers and autonomous flight modes. A lightweight, flexible sensor array, attached subtly to the airplane’s structure, could be a viable approach.

Another potential innovation is using bio-inspired designs. Studying the aerodynamics of birds or insects could lead to novel paper airplane designs that enhance lift, maneuverability, and stability.

Future Research Directions

Future research in paper airplane FPV control should focus on optimizing the design for enhanced stability and maneuverability. Researchers could explore different paper types, folding techniques, and wing shapes to identify optimal configurations for various flight conditions. Moreover, investigating the impact of environmental factors like wind and temperature on flight stability and control is vital. Further research into advanced control algorithms, capable of adapting to real-time changes in the environment, would also prove highly beneficial.

Potential Applications in Other Fields

The technology developed for paper airplane FPV control has potential applications beyond the realm of recreational flying. For example, miniature drones with similar control systems could be used in search and rescue operations, or in inspecting hard-to-reach structures. The principles of miniature, lightweight control systems could also inspire the development of smaller, more efficient robotic systems for various industrial and scientific purposes.

Potential Challenges and Limitations

A primary challenge lies in the inherent fragility of paper airplanes. Maintaining the structural integrity of the airplane while integrating sensors and control mechanisms is critical. The lightweight nature of paper also necessitates the development of ultra-low-power components for the FPV system to avoid significant power consumption. Furthermore, precise and reliable sensor data acquisition in the face of air turbulence and the small scale of the aircraft is a major hurdle.

Another limitation is the current limitations of the visual sensors for FPV systems. The size and resolution of cameras and the processing power of the onboard microcontrollers need further advancements to enable reliable real-time image analysis.

Conclusive Thoughts: Paper Airplane Fpv Control

In conclusion, controlling paper airplanes with FPV technology is a fascinating endeavor that merges age-old design principles with modern engineering. This project unveils the intricate details and innovative aspects of designing and building a fully functional FPV controlled paper airplane. We’ve explored the essential components, control systems, and software required. The future of this technology is brimming with possibilities, and the challenges presented offer a fascinating glimpse into the future of micro-flight control.