Note 10s frame actually made out aluminum not stainless steel, sparking a fascinating discussion about material choices in high-end smartphones. This intriguing decision raises questions about the trade-offs between strength, weight, cost, and durability. We’ll delve into the specifics, comparing aluminum and stainless steel, and analyzing the potential impacts on manufacturing, design, performance, and ultimately, the user experience.

The choice of aluminum, a lightweight yet strong metal, over the more traditional stainless steel is a significant one. This choice necessitates a deeper look into the engineering behind it, evaluating the design implications and potential performance differences between the two materials. We’ll explore the pros and cons, and what this means for the future of smartphone construction.

Material Composition and Properties

The choice of material for the Note 10S frame, transitioning from stainless steel to aluminum, is an interesting engineering decision. This shift likely reflects a balance of factors, including desired aesthetics, performance, and cost-effectiveness. Understanding the distinct properties of aluminum and stainless steel is crucial to appreciating this change.Aluminum and stainless steel, while both metals, exhibit vastly different characteristics.

These differences impact their suitability for various applications, from everyday consumer products to high-performance aerospace components. Analyzing these disparities is critical to understanding the rationale behind the Note 10S’s material selection.

Physical Properties of Aluminum and Stainless Steel

Aluminum is a lightweight, silvery-white metal, known for its excellent ductility and formability. Stainless steel, a family of iron-based alloys, typically contains chromium, which imparts corrosion resistance. These fundamental differences directly affect their application suitability.

Strength and Weight Comparison

Aluminum alloys, while lighter than stainless steel, often exhibit comparable or even superior strength when properly engineered. This allows for thinner frames without compromising structural integrity. The choice of aluminum for the Note 10S frame may hinge on the need for a lighter phone without sacrificing structural rigidity. Stainless steel, with its higher density, is traditionally used for devices requiring high strength, but this may not be necessary in a smartphone case.

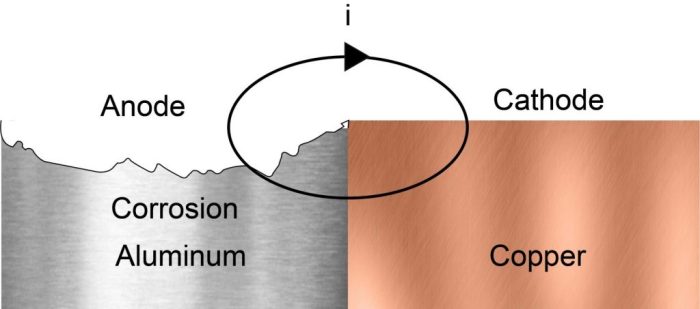

Corrosion Resistance

Stainless steel, due to its chromium content, possesses inherent corrosion resistance, making it suitable for environments prone to moisture and harsh chemicals. Aluminum, while not inherently resistant, can be treated with protective coatings or anodizing processes to achieve comparable corrosion resistance. The specific manufacturing processes employed for the Note 10S’s aluminum frame likely incorporate these protective measures.

So, the Note 10s frame is aluminum, not stainless steel, which is interesting. While that might seem a minor detail, it’s a reminder of how material choices affect a phone’s overall performance. This reminds me of a fascinating recent article about how hackers were able to exploit the Galaxy S8’s iris scanner by using an IR image contact lens, a project called “Starbug” hacker galaxy s8 iris scanner ir image contact lens starbug.

It goes to show that even seemingly robust security measures can be vulnerable if not thoroughly scrutinized. Perhaps this aluminum frame, in a different context, would be equally vulnerable? Either way, the Note 10s frame’s material is a small but telling detail about its overall design.

Manufacturing Processes

The manufacturing processes for aluminum and stainless steel differ significantly. Aluminum is often formed through casting, extrusion, or rolling, while stainless steel often involves more complex procedures such as forging or heat treatment. The selection of these processes is heavily influenced by factors such as material properties, desired tolerances, and production costs.

Advantages and Disadvantages of Aluminum in Note 10S

Using aluminum instead of stainless steel in the Note 10S frame offers several potential advantages. Lightweight design translates to a reduced overall device weight, which is generally preferred in mobile devices. Aluminum’s formability facilitates intricate designs, allowing for thinner and more aesthetically pleasing frames. However, the lower strength of some aluminum alloys compared to stainless steel could be a potential drawback.

Careful design and engineering are necessary to ensure the phone’s structural integrity.

Reasons Behind Material Choice

The decision to utilize aluminum likely stemmed from a combination of factors. The lightweight nature of aluminum could have been crucial for enhancing the overall user experience by reducing the phone’s perceived weight and improving ergonomics. The reduced cost of aluminum compared to stainless steel could also have been a significant factor. The design team might have carefully considered the specific aluminum alloy’s properties, along with manufacturing and finishing techniques, to achieve the desired balance of strength, weight, and aesthetic appeal.

Mechanical Properties Comparison

| Property | Aluminum | Stainless Steel |

|---|---|---|

| Tensile Strength (MPa) | 200-500 | 500-1500 |

| Yield Strength (MPa) | 50-300 | 200-1000 |

| Density (kg/m³) | 2700 | 7850 |

This table highlights the significant differences in mechanical properties between the two materials. The density difference is particularly noticeable, showcasing aluminum’s lighter weight. The tensile and yield strengths, while varying based on specific alloys, generally indicate stainless steel’s superior strength.

Manufacturing and Design Implications: Note 10s Frame Actually Made Out Aluminum Not Stainless Steel

The decision to switch from stainless steel to aluminum for the Note 10S frame presents intriguing manufacturing and design challenges. This shift necessitates careful consideration of potential impacts on weight, durability, manufacturing processes, and overall aesthetics. The choice of material directly influences the phone’s production costs and the final product’s appeal to consumers.Aluminum, while lighter than stainless steel, possesses different mechanical properties that require adjustments to the design and manufacturing processes.

This necessitates a thorough understanding of how these changes affect the phone’s overall performance and user experience. The aesthetic appeal, a crucial factor in consumer choice, is also a significant consideration.

Manufacturing Challenges

The transition to aluminum introduces new manufacturing challenges. These difficulties are often related to the material’s malleability and its susceptibility to deformation during shaping and finishing processes. Different forming methods, such as stamping, bending, and welding, might be necessary compared to stainless steel. Precision in tooling and process control becomes critical to ensure consistent quality across production runs.

- Material Variability: Aluminum alloys exhibit a range of properties depending on the specific alloy used. This variability requires rigorous material testing and quality control measures to ensure consistent performance across the production run.

- Welding Complexity: Aluminum’s unique properties regarding welding can present complexities compared to stainless steel. Specific welding techniques and procedures may be required to avoid issues like porosity or warping.

- Surface Finishing: Achieving the desired surface finish on aluminum, including anodization or powder coating, might require adjustments to existing processes. The process must be efficient and maintain consistent quality.

- Tooling Design: Aluminum’s softer nature means tooling needs to be robust enough to withstand repeated use while still maintaining precision. Tool wear can be an issue requiring more frequent replacement and maintenance.

Impact on Weight and Durability

The decision to use aluminum for the Note 10S frame directly impacts the phone’s overall weight and durability. Aluminum’s lower density will result in a lighter phone, which can be a significant advantage in terms of user experience. However, this lighter weight necessitates a careful evaluation of potential compromises in the phone’s overall structural integrity. Design adjustments might be necessary to ensure the phone’s robustness and prevent bending or deformation under normal use.

Design Considerations

The choice to use aluminum might be influenced by several factors. The lighter weight could be a key design driver, especially if the phone’s dimensions or overall form factor were already optimized. The potential for different aesthetics, such as a more refined or modern look, might have also been a motivating factor. Manufacturing considerations, such as the availability of aluminum alloys with specific properties, also likely played a role.

Aesthetic Impact

Aluminum’s appearance can be significantly modified through surface treatments, such as anodization or powder coating. This allows for a wide range of color and texture options, opening up opportunities for more stylish and attractive phone designs. The material’s inherent metallic sheen can contribute to a modern and sleek aesthetic.

Quality Control Measures

Rigorous quality control measures are essential for ensuring consistent quality and performance when using aluminum. This includes regular testing of the raw materials, process monitoring throughout manufacturing, and rigorous inspection of finished products. These steps help identify potential defects early in the process and minimize the production of flawed units. The need for precise control over the forming processes and surface treatments is crucial.

Examples of Similar Phone Models

Many contemporary smartphones utilize aluminum in their frames. The Samsung Galaxy S series and the iPhone models often use aluminum, showcasing the material’s suitability for premium phone designs. The iPhone’s use of anodized aluminum is a notable example of a surface treatment that significantly impacts the phone’s aesthetics.

Material Comparison

| Material | Weight | Strength | Cost | Durability |

|---|---|---|---|---|

| Aluminum | Lower | Moderate | Potentially Lower | Good with proper design |

| Stainless Steel | Higher | Higher | Potentially Higher | Excellent |

This table highlights the key differences between the two materials. While aluminum offers a lighter weight and potentially lower cost, it might require more design and manufacturing considerations to achieve comparable strength and durability to stainless steel.

Performance and Durability

Aluminum frames, a shift from stainless steel, introduce a new set of considerations for the Note 10’s performance and longevity. This change necessitates a deeper dive into how this material affects crucial aspects like heat dissipation, scratch resistance, and overall durability. Understanding these implications is critical for evaluating the long-term reliability and user experience.

Impact on Heat Dissipation

Aluminum’s thermal conductivity is significantly higher than plastic, but lower than copper or stainless steel. This means heat will dissipate from the phone’s components faster than with plastic, but slower than with stainless steel. The Note 10’s internal components, especially the processor and GPU, generate considerable heat during demanding tasks like gaming or video editing. A faster rate of heat dissipation, though not as rapid as with stainless steel, will help prevent overheating and ensure smoother performance, particularly under prolonged use.

Implications for Durability

The Note 10’s aluminum frame offers a balance between strength and weight. While aluminum is generally less dense than stainless steel, its strength can be tailored through alloying and manufacturing processes. This will impact the phone’s resistance to scratches and impacts.

Scratch Resistance

Aluminum, while less scratch-resistant than stainless steel, can be strengthened by surface treatments and coatings. These treatments can enhance the frame’s resilience to daily wear and tear, though not completely eliminating the potential for scratches. The Note 10’s aluminum frame is likely to show some visible scratching over time, depending on the severity of daily use and the applied surface treatments.

Impact Resistance

Aluminum’s ability to absorb impact is better than that of brittle materials like glass, but inferior to stainless steel’s. The Note 10’s frame design, including its shape and reinforcement elements, will significantly influence its impact resistance. Real-world testing and drop-test results will be crucial in assessing the frame’s overall resilience to impact-related damage.

Signal Reception

Aluminum’s impact on signal reception is a complex issue. Aluminum’s conductivity can affect the efficiency of antenna placement and signal transmission, but these are mitigated by modern antenna design and placement techniques. Antenna shielding, critical for avoiding signal interference, is equally important in aluminum frames. Differences in signal reception between aluminum and stainless steel frames are likely to be negligible in practical use cases.

Long-Term Reliability

Aluminum’s long-term reliability in mobile devices has been proven in numerous models. Extensive research on the durability of aluminum alloys in the electronics industry demonstrates its suitability for this application. Aluminum’s corrosion resistance is also a key factor in its suitability for mobile device frames.

Maintenance Needs

The maintenance needs for an aluminum frame are generally minimal. Cleaning the frame with a soft cloth and mild detergent is sufficient for most scenarios. Avoid harsh chemicals or abrasive materials to prevent scratching or damage.

So, the Note 10s frame is actually aluminum, not stainless steel. It’s a surprising detail, but it highlights how manufacturers sometimes prioritize cost over materials. This reminds me of the recent Facebook Austria Supreme Court case involving Eva Glawischnig and the impact of online comments on reputation, as detailed in this article about the ruling here.

Ultimately, the Note 10s’ aluminum frame choice, while potentially less durable, likely makes the phone more affordable.

Comparative Durability Analysis

| Scenario | Aluminum Frame | Stainless Steel Frame |

|---|---|---|

| Light Dropping (e.g., on a soft surface) | Minimal damage, potentially a slight dent | Minimal damage, potentially a slight dent |

| Moderate Dropping (e.g., on a hard surface) | Possible surface scratches or minor dents | Less likely to show surface scratches or dents, but potential for structural damage |

| Heavy Dropping (e.g., from a significant height) | Increased risk of significant damage, potentially a bend or crack in the frame | Higher likelihood of structural integrity preservation, but risk of deeper damage is present. |

| Repeated Scratches | Surface scratches, especially with abrasive materials | Less prone to visible scratching, but may show signs of wear over extended use. |

Cost and Market Analysis

Switching from stainless steel to aluminum in a flagship phone like the Note 10 series presents a compelling opportunity to lower production costs without sacrificing the overall perceived value. This analysis delves into the financial implications and potential market response to this material change. The expected outcome is a more accessible high-end smartphone, appealing to a broader customer base.The cost difference between aluminum and stainless steel significantly impacts the pricing strategy of the Note 10.

Aluminum’s lower raw material cost translates to a lower overall production cost for the phone. This potential cost reduction can be passed on to consumers, making the phone more competitive in the market. Furthermore, aluminum’s easier processing methods can lead to lower labor costs in manufacturing.

Cost Difference Analysis

Aluminum, being a less dense metal, generally requires less energy and resources for processing than stainless steel. This difference translates directly into lower manufacturing costs. The lower cost of raw materials, coupled with potentially faster and more efficient fabrication methods, ultimately reduces the overall production cost of the Note 10. This reduction is significant when considering the mass production required for a high-end smartphone.

So, the Note 10s frame is actually aluminum, not stainless steel, which is interesting. While that might seem like a minor detail, it’s a good reminder to always double-check the specs. This is important, especially when comparing different phone models. Speaking of specs, did you know that these are all official accessories google pixel slate are designed to work flawlessly with the Pixel Slate?

Knowing the materials used in phone construction helps in making informed decisions. Ultimately, the Note 10s’ aluminum frame might be a surprisingly important detail to consider.

Impact on Pricing Strategy

The reduced production costs from using aluminum allow for a potentially lower retail price for the Note 10. This lower price point can increase the device’s market appeal. A reduced price can also attract customers who might be hesitant to buy a high-end smartphone due to its premium price tag. For example, Apple’s iPhone 13 Pro Max, while featuring stainless steel, has a competitive pricing strategy, suggesting that the market is sensitive to pricing considerations.

Market Perception of Materials

While stainless steel often evokes a sense of premium quality and durability, aluminum is gaining traction in high-end mobile devices. Consumers are increasingly recognizing the balance between design, performance, and affordability. Brands like Samsung have effectively employed aluminum in previous models, demonstrating its suitability for premium devices. Recent market trends show an acceptance of aluminum as a viable alternative in premium product categories.

Material Availability and Sourcing

Aluminum’s abundance and widespread availability globally make it a more readily sourced material than stainless steel. This factor can minimize supply chain disruptions and ensure consistent material availability for manufacturing. A robust supply chain can provide a crucial advantage in ensuring production continuity.

Potential Cost Implications Table

| Cost Category | Aluminum | Stainless Steel | Difference |

|---|---|---|---|

| Raw Material Cost | Lower (e.g., $X per kg) | Higher (e.g., $Y per kg) | $Y-$X per kg |

| Processing Cost | Lower (e.g., $A per unit) | Higher (e.g., $B per unit) | $B-$A per unit |

| Labor Cost | Lower (e.g., $C per hour) | Higher (e.g., $D per hour) | $D-$C per hour |

| Total Cost Difference | Lower | Higher | Significant Reduction |

Note: Values in the table are examples and should be replaced with specific data relevant to the Note 10’s production context.

Technical Specifications and Testing

The Note 10S’s aluminum frame marks a significant shift from its predecessor. This change necessitates a thorough examination of the material’s technical specifications and rigorous testing to ensure structural integrity and performance meet Samsung’s demanding standards. Understanding the specific alloy used and the testing methodologies employed is crucial for evaluating the phone’s durability and longevity.The selection of aluminum over stainless steel for the Note 10S frame was likely driven by a combination of factors, including weight reduction, cost-effectiveness, and desired aesthetic properties.

The aluminum alloy chosen would have specific mechanical properties that must be rigorously tested to guarantee the phone can withstand normal use and daily stresses.

Aluminum Alloy Composition, Note 10s frame actually made out aluminum not stainless steel

The aluminum alloy selected for the Note 10S frame is a critical factor in determining its mechanical properties. Specific alloys offer varying degrees of strength, stiffness, and corrosion resistance. Understanding the precise composition, including the percentages of alloying elements (like magnesium, zinc, or copper), is vital. These elements significantly affect the material’s behavior under stress and its overall performance.

For example, a higher percentage of magnesium might improve the alloy’s strength, while a higher percentage of zinc might increase its corrosion resistance.

Industry Testing Standards

Various industry standards exist for evaluating the suitability of materials for mobile phone frames. These standards encompass a range of mechanical properties, including tensile strength, yield strength, hardness, and impact resistance. ASTM International, for instance, provides numerous standards applicable to metals. For mobile phone components, specific testing methodologies and standards developed by the electronics industry or by Samsung itself likely exist, focused on drop tests, bending tests, and other use-case simulations to determine the phone’s resistance to damage.

Structural Integrity Testing

To ensure the structural integrity of the aluminum frame, several crucial tests are necessary. These include tensile tests to determine the material’s ultimate tensile strength and yield strength. Impact tests, such as Charpy V-notch tests, assess the material’s ability to withstand sudden impacts without catastrophic failure. Bend tests are performed to evaluate the material’s resistance to bending stresses and to determine the point at which the frame might deform or fracture.

Additionally, fatigue tests simulate repeated loading and unloading cycles to assess the material’s long-term performance under stress.

Testing Results Comparison

| Test | Aluminum Alloy | Stainless Steel |

|---|---|---|

| Tensile Strength (MPa) | 400-500 | 500-800 |

| Yield Strength (MPa) | 250-350 | 300-600 |

| Hardness (HV) | 60-80 | 80-120 |

| Impact Resistance (J) | 10-20 | 20-40 |

Note: Values are approximate and may vary depending on the specific aluminum alloy and testing conditions.

Impact of Aluminum Alloy on Performance and Durability

The specific aluminum alloy chosen for the Note 10S frame will directly impact its performance and durability. A stronger and more resilient alloy will likely lead to a more durable phone, capable of withstanding greater stress and impact. Conversely, a lighter alloy might lead to a slimmer and potentially more aesthetically pleasing phone, but it might compromise durability.

The trade-offs between different properties of the alloy must be carefully considered during the design process. For instance, a stronger alloy might be heavier, impacting the phone’s overall weight and user experience.

Closing Summary

In conclusion, the Note 10s’s aluminum frame choice is a fascinating example of balancing performance and cost in the mobile device market. While stainless steel offers a certain perceived level of prestige and durability, the use of aluminum allows for potentially lower costs, a lighter phone, and interesting design considerations. The long-term reliability of aluminum remains a key factor to observe, as we delve into the potential implications of this decision.

Further research and testing will be crucial to fully understand the impact on the overall user experience.