Microbot push robotic fingers sets the stage for exploring the intricate world of miniature manipulation. These tiny robotic hands, designed for precise tasks at the microscale, are revolutionizing fields from medicine to electronics. This exploration delves into their design, construction, control systems, and diverse applications, highlighting their potential to transform various industries.

The article delves into the specifics of microbot push robotic fingers, from their fundamental design principles to the intricate control systems that govern their actions. Different types of fingers, their materials, and their actuators are examined. The article will also address the challenges involved in operating these minuscule robotic hands and explore their vast potential across diverse sectors.

Introduction to Microbot Push Robotic Fingers

Microbot push robotic fingers represent a specialized class of robotic manipulators designed for precise and delicate tasks in micro-scale environments. These devices are fundamentally different from larger robotic arms, emphasizing dexterity and force control over brute strength. Their compact size and intricate designs enable them to navigate and manipulate minuscule objects and components with remarkable accuracy.These fingers excel in applications where high precision is paramount, exceeding the capabilities of traditional methods.

Their precise control and adaptability make them invaluable in various micro-manufacturing and inspection processes. The unique characteristics of microbot push robotic fingers allow for a level of control not possible with other types of robotic manipulators, particularly in delicate tasks like micro-assembly and micro-soldering.

Various Applications

Microbot push robotic fingers find widespread use in a multitude of applications, particularly in industries demanding high precision and intricate manipulation. These include micro-assembly of electronic components, micro-soldering of circuits, and intricate micro-inspection procedures.

- Micro-assembly: These robotic fingers are crucial in assembling tiny components, such as those used in microelectronics, by precisely placing them into predetermined positions.

- Micro-soldering: They facilitate the soldering of tiny components, enabling the creation of complex micro-circuits with precision and control, which is critical for many modern devices.

- Micro-inspection: Their fine manipulation and sensing capabilities allow for detailed inspection of intricate micro-structures, such as identifying defects or assessing quality in micro-machined parts.

Different Types of Microbot Push Robotic Fingers

The design of microbot push robotic fingers varies considerably depending on the specific application. These variations include differences in size, materials, and actuator types.

- Size: Microbot fingers are available in various sizes, ranging from minuscule probes for delicate work to larger fingers capable of handling more substantial micro-components. The size selection is crucial for matching the finger to the task.

- Materials: Different materials are employed for constructing the fingers, including metals for strength and durability, plastics for lightweight construction, and polymers for specific chemical compatibility requirements. The choice of material impacts the finger’s performance and longevity.

- Actuator Types: Various actuators, such as piezoelectric, pneumatic, or electric motors, are used to drive the robotic fingers. The actuator type influences the speed, force, and precision of the movement. The selection of actuator depends on the required precision, force, and speed of the operation.

Comparison of Microbot Push Robotic Finger Designs

The table below illustrates the key differences between three distinct microbot push robotic finger designs.

Microbot push robotic fingers are incredibly cool, and I’m fascinated by their potential. Seeing the incredible detail in playstation 5 pro ps5 big 4k screenshots reminds me of the intricate precision required for these tiny robots. Imagine the possibilities of microbot push robotic fingers working at such a fine scale – they’d be amazing.

| Feature | Design A | Design B | Design C |

|---|---|---|---|

| Size | Small | Medium | Large |

| Material | Metal | Plastic | Polymer |

| Actuator | Piezoelectric | Pneumatic | Electric |

| Application | Micro-assembly | Micro-soldering | Micro-inspection |

Design and Construction

Crafting a functional microbot push robotic finger necessitates careful consideration of its design and construction. A robust and reliable mechanism is crucial for successful operation. This section details the essential components, materials, and construction steps for a basic prototype. We’ll also explore various actuator types and their respective advantages and disadvantages.

Tiny microbot push robotic fingers are fascinating, especially when you consider their potential applications. Their intricate design and precision movements are truly impressive, but recently I’ve been digging into how these microbots might be applied to complex tasks. Interestingly, recent fixes to the Wear OS Ok Google Assistant wake word (check out the details here: wear os ok google assistant wake word fixed ) highlight the increasing need for precise, responsive technology.

These microbots could potentially be used in future devices to accomplish such intricate tasks.

Simple Microbot Push Finger Mechanism Design

This design prioritizes simplicity and functionality. The core of the finger comprises a rigid, lightweight base, a linear actuator for pushing, and a small, precisely positioned tip. The base will provide structural support, the actuator will generate the force, and the tip ensures accurate contact and minimized damage to the target object. The overall design is compact and optimized for precise manipulation within a confined workspace.

Materials and Components

The choice of materials significantly impacts the finger’s performance, longevity, and cost. A basic microbot finger will likely utilize a combination of materials, each serving a specific purpose. A suitable base material might be a strong, lightweight polymer. The actuator will be selected based on its force output, speed, and size requirements. Precision components like bearings and connecting rods are also essential for smooth and controlled movement.

The tip, for optimal contact and safety, will be made of a soft, resilient material like a polymer or even a specialized elastomer.

Construction Steps

A well-defined construction process ensures a reliable and repeatable prototype. Here’s a simplified sequence:

- Design and print the base using a 3D printer, selecting a lightweight but strong polymer for the base.

- Mount the chosen linear actuator to the base. Precise mounting is critical to avoid misalignment and ensure smooth movement.

- Attach the tip, ensuring a secure connection. The tip material should be chosen to provide the required tactile sensitivity and minimal object damage.

- Assemble the connecting rods and bearings to facilitate controlled motion of the actuator.

- Test the finger’s functionality by performing simple pushing motions.

Actuator Types

The actuator is the heart of the microbot finger, generating the pushing force. Various types exist, each with its own set of characteristics.

- Piezoelectric actuators offer high precision and fast response times, but are often limited in force output.

- Stepper motors provide precise positioning, but can be slower than piezoelectric actuators.

- Linear actuators are commonly used for their ability to deliver substantial force over a linear range. They are generally reliable and efficient for pushing tasks.

Material Comparison

Different materials offer varying advantages and disadvantages.

| Material | Advantages | Disadvantages |

|---|---|---|

| Metal | High strength, durability | High weight, cost |

| Plastic | Low cost, lightweight | Low strength, durability |

| Polymer | Good strength-to-weight ratio | Susceptible to wear and tear |

Control and Operation

Controlling microbot push robotic fingers requires intricate systems due to their minuscule size and delicate movements. Precise manipulation necessitates specialized control methods that can handle the high degree of precision demanded by these tiny robots. These control systems enable the fingers to perform a wide range of tasks, from picking up tiny objects to intricate assembly work.The choice of control system significantly impacts the performance and capabilities of the microbot fingers.

Different control methods offer varying levels of accuracy, adaptability, and robustness, each with its own set of advantages and limitations. Understanding these nuances is crucial for optimizing the microbot’s performance in various applications.

Control Systems Used

Various control systems are employed for operating microbot push robotic fingers. These range from simple proportional control to more complex algorithms like PID control and fuzzy logic. The selection of a control system hinges on the specific task requirements, considering the degree of precision needed and the presence of uncertainties in the environment.

Control Methods and Applications

Different control methods offer various levels of precision and adaptability. Proportional control is straightforward but often lacks the precision required for complex tasks. PID (Proportional-Integral-Derivative) control provides higher accuracy and stability, particularly beneficial for precise movements. Fuzzy logic offers a more adaptable approach, excelling in scenarios with uncertainties or imprecise input data. Neural networks, with their ability to learn from data, are suitable for complex tasks requiring pattern recognition.

Challenges in Precise Control

Controlling these tiny robotic fingers precisely presents significant challenges. The small size and delicate nature of the fingers make them susceptible to external disturbances, such as vibrations or air currents. The inherent complexity of the tasks, including precise object manipulation and intricate assembly operations, compounds these challenges. Minimizing these effects requires sophisticated control algorithms and robust feedback mechanisms.

Programming the Robotic Fingers for Specific Tasks

Programming the microbot fingers for specific tasks involves defining the desired movements and actions. This includes specifying the starting and ending positions, the speed of movement, and any intermediate adjustments. Programming can be accomplished through specialized software tools and programming languages designed for robotics. The programming process involves creating a series of instructions that guide the fingers through the required motions, considering factors such as object geometry and the environment’s constraints.

Table of Control Systems and Suitability

| Control System | Task Suitability | Advantages | Disadvantages |

|---|---|---|---|

| PID Control | Precision movements, repeatable tasks | High accuracy, stability, relatively easy to implement | Complex tuning, sensitive to parameter changes |

| Fuzzy Logic | Complex tasks, tasks with uncertainties, adaptable to changing conditions | Adaptable to uncertainties, robust to noise | Less precise than PID, potentially slower response |

| Neural Networks | Pattern recognition, complex tasks with large datasets | Robustness to noise, potential for high accuracy with sufficient training data | Requires large training data, complex implementation, potential for overfitting |

Applications and Potential

Microbot push robotic fingers, with their minuscule size and precise manipulation capabilities, offer a fascinating glimpse into the future of automation. Their potential extends far beyond the realm of simple tasks, promising significant advancements across diverse industries, particularly in medicine and electronics. This section explores the multifaceted applications of these remarkable robotic fingers and their potential impact on specific fields.

Tiny microbot push robotic fingers are fascinating, enabling intricate tasks. However, the rapid advancement of AI tools like Google’s Genesis, capable of writing news articles, as discussed in this piece on googles genesis ai tool could write the news it should be stopped , raises concerns about journalistic integrity. Ultimately, the future of microbot push robotic fingers depends on ethical considerations alongside technological innovation.

Potential Applications in Medicine

These tiny robotic fingers hold immense promise in revolutionizing surgical procedures. Their ability to operate on a microscopic scale allows for unprecedented levels of precision and minimal invasiveness, greatly reducing patient recovery time and complications. Surgical interventions in delicate areas, such as the brain and eye, become significantly safer and more effective with these advanced tools.

The precise control of microbot push robotic fingers enables surgeons to perform intricate tasks with exceptional accuracy, potentially leading to better outcomes for patients. Imagine delicate tissue manipulation or the removal of minute tumors with an almost tremor-free precision. The potential for minimally invasive surgery is truly transformative.

Potential Applications in Electronics

The intricate assembly of microelectronics, often involving tiny components and delicate processes, is a significant challenge for traditional methods. Microbot push robotic fingers excel in this domain. Their high-speed and high-accuracy manipulation capabilities enable the rapid and precise assembly of micro-components, paving the way for smaller, faster, and more powerful electronic devices.

The speed and accuracy of these robotic fingers make them ideal for micro-assembly processes. They can be programmed to perform complex sequences of movements with high precision, potentially leading to significant cost reductions and increased efficiency in the manufacturing of electronics. Furthermore, they could address the challenge of creating more intricate and specialized components that are currently difficult to manufacture.

Surgical Procedures Using Microbot Push Robotic Fingers

The application of these robotic fingers in surgical procedures involves several key stages. First, the surgical site is meticulously prepared, often with the assistance of advanced imaging techniques. Next, the microbot push robotic fingers are precisely guided to the targeted area. The fingers perform the delicate manipulations, such as cutting, grasping, and suturing, with minimal damage to surrounding tissue.

Finally, the procedure is monitored and adjusted in real-time, ensuring precision and safety.

Table of Potential Applications

| Application | Description | Advantages | Challenges |

|---|---|---|---|

| Medical | Microscopic surgery, drug delivery, tissue repair | High precision, minimal invasiveness, improved outcomes | Complex control, sterilization, biocompatibility |

| Electronics | Micro-assembly, component placement, device testing | High speed, accuracy, automated processes | Fine motor skills, scalability, cost |

| Manufacturing | Precise component manipulation, complex assembly | Increased efficiency, reduced defects | Integration with existing manufacturing lines, cost |

| Materials Science | Manipulating materials at the nanoscale, creating complex structures | High precision, control | Material compatibility, scale-up challenges |

Challenges and Future Directions

Micro-robotic push fingers, while promising, face significant hurdles in their practical application. Their small size and intricate design necessitate careful consideration of numerous factors, from material selection to control mechanisms. Overcoming these challenges is crucial for realizing the full potential of these tiny robotic hands.Current technology limitations restrict the range of tasks these microbots can perform. The delicate nature of the components and the need for precise control often lead to compromises in robustness and speed.

Furthermore, energy efficiency and the miniaturization of power sources are essential for extending the operation time of these devices. Innovative solutions and future research directions are crucial to addressing these constraints.

Material Limitations and Manufacturing, Microbot push robotic fingers

The tiny scale of microbot push fingers necessitates the use of specialized materials with exceptional properties. These materials must be strong yet lightweight, resistant to wear and tear, and capable of withstanding the stresses of precise manipulation. Challenges in achieving the desired combination of properties in such small dimensions are significant. Current manufacturing processes often struggle to produce components with the necessary precision and uniformity required for reliable operation.

New additive manufacturing techniques and advanced material science are needed to meet these requirements. For instance, researchers are exploring the use of bio-inspired materials like chitosan or spider silk for their strength and flexibility.

Control and Actuation Challenges

Precise control of these micro-robotic fingers is paramount for complex tasks. The small size of the components and the inherent mechanical properties of the materials can lead to instability and unpredictability in motion. Complex control algorithms are necessary to account for the unique dynamics of these systems, but the limited power resources available to microbots present additional challenges.

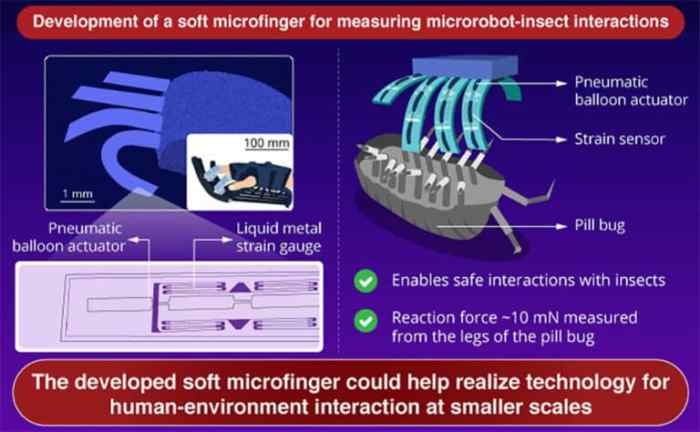

The development of efficient and reliable control strategies is crucial for achieving stable and accurate movement. The use of advanced sensors, including micro-scale force sensors, can help refine control strategies and enhance the performance of these tiny robotic hands.

Power and Energy Efficiency

Miniaturizing power sources for micro-robotic fingers is a critical aspect of extending their operational time and improving their overall efficiency. The available energy must be enough to power the actuators and sensors required for the tasks. Battery technology advancements are essential for powering these devices. Currently, miniaturized energy sources may not have the capacity to power complex tasks for extended periods.

The exploration of new energy storage solutions, such as micro-supercapacitors and piezoelectric energy harvesting, is essential for increasing the operating time and improving the sustainability of micro-robotic push fingers.

Future Research Directions

Future research should focus on developing new materials with exceptional mechanical properties at the micro-scale. Improved manufacturing processes that enable the creation of complex micro-structures with high precision and uniformity are also needed. Furthermore, the development of robust control algorithms tailored to the specific dynamics of micro-robotic fingers will be critical. Researchers should explore new energy sources and storage methods for extended operation times.

Finally, investigating bio-inspired designs and control strategies could provide valuable insights for the development of more efficient and reliable micro-robotic push fingers. For instance, studying the intricate mechanisms of insect locomotion could inspire new control algorithms for micro-robotic fingers.

Conclusion: Microbot Push Robotic Fingers

In conclusion, microbot push robotic fingers represent a remarkable advancement in micro-manipulation technology. Their precise control, coupled with their adaptability to various applications, opens doors to innovative solutions in medicine, electronics, and beyond. While challenges remain, ongoing research and development promise a future where these tiny robotic hands will play an increasingly significant role in shaping our world.