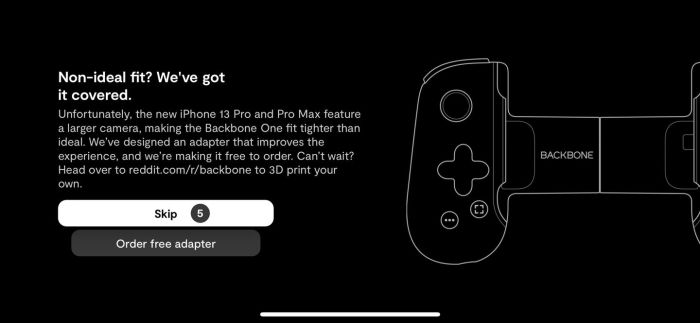

Backbone controller iPhone 13 Pro camera bump 3D printed adapter opens up a world of possibilities for enhancing your mobile gaming experience. This adapter, meticulously crafted through 3D printing, provides a stable and secure platform for mounting various accessories, like game controllers, to your iPhone 13 Pro. It’s designed to perfectly fit the camera bump, offering a custom-made solution that maximizes functionality and preserves the phone’s aesthetic.

From lens protection to expanded functionality, this adapter caters to diverse needs. The design considerations, manufacturing processes, and a range of compatible accessories are all meticulously explored. This guide delves into the specifics of 3D printed adapters, exploring materials, design choices, and the practical applications in different environments. The guide also includes a comprehensive cost analysis, offering a balanced perspective on the financial aspects involved.

Introduction to 3D Printed Adapters for iPhone 13 Pro Camera Bump

The iPhone 13 Pro boasts a distinctive camera bump, a raised area housing its advanced camera system. This design, while enhancing image quality, can present challenges for users seeking diverse accessories or mounting solutions. The bump’s substantial height can interfere with certain cases, tripods, or other camera attachments.D printed adapters are becoming a popular solution to address these compatibility issues.

These custom-designed pieces precisely fit the contours of the camera bump, enabling seamless integration with various accessories. This allows users to maintain both the protective case and the functionality of their desired mounts, a significant improvement over generic solutions that often don’t fit properly.

Overview of iPhone 13 Pro Camera Bump Design

The iPhone 13 Pro’s camera bump is a key design element, enhancing the phone’s imaging capabilities. However, its elevated profile presents challenges when integrating with different accessories. The precise shape and dimensions of this bump are critical factors in designing compatible adapters.

Need for 3D Printed Adapters

The need for 3D printed adapters arises from the specific design of the iPhone 13 Pro’s camera bump. Standard accessories may not fit snugly, potentially damaging the phone or compromising functionality. 3D printed adapters offer a custom solution, ensuring a perfect fit and preventing any potential damage.

Use Cases for 3D Printed Adapters

These adapters have several practical applications. They can be used for securing the phone on tripods for photography, attaching external lenses, or creating unique mounts for specific accessories. Users can even design their own custom solutions to accommodate unusual accessories, ensuring compatibility without compromising the phone’s protection.

Common Materials Used in 3D Printing Adapters

Common materials for 3D printing these adapters include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and PETG (Polyethylene Terephthalate Glycol). PLA is a popular choice for its biodegradability and affordability. ABS offers greater durability and heat resistance, making it suitable for demanding applications. PETG combines the benefits of both, balancing cost, durability, and flexibility.

Advantages of 3D Printing over Other Methods

D printing offers several advantages over traditional manufacturing methods for creating these adapters. Its flexibility allows for rapid prototyping and customization, enabling users to quickly create unique designs. The cost of creating small batches of custom adapters is also significantly lower compared to traditional manufacturing. Furthermore, the ability to produce intricate shapes and precise fits is unmatched by other methods.

Types of 3D Printed Adapters

| Type | Material | Application |

|---|---|---|

| Tripod Mount | PLA, ABS | Securely mounting the phone on a tripod for photography |

| External Lens Mount | ABS, PETG | Attaching external lenses to the phone for macro photography or other special effects |

| Case-Compatible Mount | PLA, PETG | Creating mounts that fit seamlessly with a protective case, without compromising its protection. |

| Custom Accessory Mounts | PLA, ABS, PETG | Designing unique mounts for specific accessories, such as specific lights, microphones, or even small projectors. |

Design Considerations for 3D Printed Adapters

Creating 3D printed adapters for the iPhone 13 Pro camera bump requires careful consideration of several key elements. These adapters need to not only fit snugly but also provide a secure and stable platform for various accessories, ensuring both functionality and aesthetic appeal. The design process demands attention to detail, from structural integrity to accessory compatibility, ultimately leading to a well-rounded product.Careful consideration of design elements is crucial to ensure a high-quality 3D printed adapter.

The interplay of form and function dictates the adapter’s effectiveness and user experience. A robust design will ensure the longevity of the product, and compatibility with a variety of accessories will enhance its versatility.

Structural Integrity and Stability

Ensuring structural integrity is paramount for a 3D printed camera bump adapter. A weak or unstable design will compromise the security of attached accessories and potentially damage the iPhone’s camera. This stability is vital for preventing accidental detachment and ensuring the smooth operation of any camera accessories. The material selection and design principles need to address potential stress points and ensure the adapter can withstand typical usage scenarios.

Reinforcements or support structures may be necessary to enhance structural integrity, especially when considering the weight of attached lenses or filters.

Compatibility with Different Accessories

The adapter must accommodate a range of accessories, including lens filters, macro lenses, and other camera attachments. Careful measurement and precise design are essential to ensure a snug and secure fit for different accessory sizes and shapes. The adapter’s design should account for the variety of accessory mounting mechanisms.

Mounting Mechanisms

Different mounting mechanisms can be employed for the adapter. A simple clip-on design can be suitable for lightweight accessories, while a more complex screw-in mechanism may be necessary for heavier lenses or filters. The choice of mounting mechanism should consider the desired level of security, ease of attachment, and the overall aesthetic of the adapter. Thorough testing is needed to confirm that the selected mounting mechanism can withstand the forces experienced during use.

Aesthetics and Fit

The adapter’s design should prioritize a clean and aesthetically pleasing appearance. Careful consideration of the adapter’s profile, contours, and surface finishes can create a harmonious integration with the iPhone 13 Pro’s design. The adapter should have a smooth transition from the camera bump, enhancing the overall visual appeal of the iPhone. The precise fit of the adapter on the camera bump is critical to prevent any gaps or misalignments that could impact the quality of the attached accessories.

Camera Lens Protection Designs

Various designs can be considered for camera lens protection. Different designs can be organized in a table format to showcase the comparative features and suitability for different lens types.

| Design Type | Description | Pros | Cons |

|---|---|---|---|

| Clip-on Filter Holder | A simple clip-on design to secure filters. | Easy to use, lightweight. | Limited support for larger filters. |

| Screw-on Lens Mount | A mount with threads to secure larger lenses or filters. | Robust support, accommodates heavier accessories. | More complex design, potential for misalignment. |

| Modular Design | A design that allows interchangeable lens mounts. | Versatile, adaptable to different accessories. | More complex and potentially more expensive. |

Manufacturing and Printing Processes

Creating 3D-printed camera bump adapters requires careful consideration of the manufacturing process. Choosing the right 3D printing technology, material, and printing settings directly impacts the adapter’s quality, fit, and durability. This section delves into the crucial aspects of bringing your 3D model to life.

3D Printing Technologies

Different 3D printing technologies offer varying capabilities. For camera bump adapters, Fused Deposition Modeling (FDM) is a popular choice due to its affordability and relatively straightforward setup. Stereolithography (SLA) or Selective Laser Sintering (SLS) are also suitable, but generally come with a higher price point. FDM’s ability to produce strong, functional prototypes makes it a cost-effective option for many makers.

SLA, known for its smooth surface finish, is often preferred for highly detailed and aesthetically pleasing parts, though it might not be ideal for every application. The choice hinges on the desired level of detail, budget, and time constraints.

I’ve been tinkering with a 3D printed adapter for my iPhone 13 Pro’s camera bump, specifically for use with a backbone controller. It’s a pretty cool project, but I’ve also been thinking about the broader implications of health initiatives like measles vaccination, particularly during disease outbreaks. The economic impact of such situations, as explored in this fascinating article on measles vaccination health disease outbreak economics , is something that needs serious consideration.

Hopefully, this adapter will be just as effective as those efforts in promoting better health outcomes, while also helping me capture great action shots.

Filament Materials

The material selection is crucial for the adapter’s performance. Common filament materials include PLA, ABS, PETG, and TPU. PLA, a bio-degradable polymer, is often preferred for its ease of printing and relatively low cost. ABS is known for its strength and rigidity, which is useful for parts that need to withstand considerable force. PETG combines the advantages of PLA and ABS, offering a balance of strength, flexibility, and durability.

TPU, a flexible material, is suitable for adapters that need to provide a snug, but not overly tight fit. Each material has unique properties, influencing the adapter’s final characteristics.

3D Model Creation

Designing a precise 3D model is paramount. Software like Tinkercad, Fusion 360, or Blender allows you to create the adapter’s shape, including necessary features like precise cutouts for the camera lens. Accurate dimensions and tolerances are crucial for the adapter to function correctly and ensure a snug fit on the iPhone 13 Pro. Using reference images of the iPhone’s camera bump and existing adapters can help you create an accurate model.

Creating a functional model requires a deep understanding of the target device’s geometry and dimensions.

Post-Processing Techniques

Post-processing significantly improves the adapter’s quality. Support structures, often generated by the 3D printing software, need to be carefully removed. Cleaning the printed part of any excess material and applying a smoothing agent can significantly improve the adapter’s aesthetics and feel. Finishing touches like sanding or painting can be added to further enhance the appearance. These steps can improve the adapter’s overall quality and aesthetics.

Printing Settings and Their Impact

The printing settings significantly impact the adapter’s quality. Different settings affect the strength, surface finish, and layer adhesion of the printed part. Experimentation is often necessary to find the optimal settings for a particular material and printer. Here’s a table illustrating the impact of some crucial settings:

| Setting | Description | Impact on Adapter Quality |

|---|---|---|

| Layer Height | Distance between printed layers | Lower layer height improves detail but can increase printing time. Higher layer height results in a less detailed part, but can reduce printing time. |

| Print Speed | Rate at which the printer moves | Higher speeds can lead to less dense parts, while lower speeds produce a more solid, but slower, print. |

| Infill Density | Percentage of infill material | Higher density results in a stronger part, but can increase printing time. Lower density reduces strength and printing time. |

| Nozzle Temperature | Temperature of the filament extruder | Improper nozzle temperature can cause stringing or warping. Optimal temperature ensures proper filament extrusion and bonding. |

Finding the right balance of these settings is crucial for creating a high-quality adapter. Testing different settings and iterating on your design is a key aspect of 3D printing.

Applications and Accessories: Backbone Controller Iphone 13 Pro Camera Bump 3d Printed Adapter

D printed camera bump adapters open up a world of possibilities for iPhone 13 Pro users, transforming how they interact with their device. Beyond simply protecting the camera bump, these adapters allow for a wide array of accessories and use cases, from enhanced photography to improved usability in various environments. Understanding these applications is crucial for maximizing the value of these adapters.These adapters are not just a simple protective casing; they serve as a platform for attaching a wide variety of accessories, significantly enhancing the functionality and usability of the iPhone 13 Pro.

The versatility of 3D printing allows for customization and tailored solutions for specific needs, creating a personalized experience for each user.

Accessory Compatibility

The design of the 3D printed adapter is a key factor in determining the accessories it can accommodate. Different adapter designs cater to different needs and accessories, and the design must account for the size and shape of the accessory. For instance, a mount designed for a tripod will have different requirements than a mount for a small LED light.

Consideration of these differences ensures compatibility and optimal functionality.

Use Cases in Different Environments, Backbone controller iphone 13 pro camera bump 3d printed adapter

D printed camera bump adapters are highly adaptable to diverse environments. A rugged, outdoor-oriented adapter design can accommodate a wide range of mounts and accessories ideal for hiking or outdoor sports, like a robust tripod mount. Conversely, a more delicate and streamlined design might be better suited for everyday use and can integrate with accessories like small, compact LED lights or close-up filters.

These adaptable designs enhance the device’s functionality and usability in specific situations.

Examples of Compatible Accessories

A wide array of accessories can be used with 3D printed camera bump adapters. Tripods, selfie sticks, external microphones, and various photography accessories are all potential options. Even accessories like small LED lights for low-light photography or specialized close-up filters can be attached, expanding the creative possibilities. The range of compatible accessories is limited only by the imagination and the specific design of the adapter.

Table of Compatible Accessories

| Accessory Type | Adapter Design Requirements |

|---|---|

| Tripods | Requires a robust mount with sufficient surface area for stable connection. Thread sizes and mounting configurations should be considered. |

| Selfie Sticks | The adapter should provide a secure and stable mounting point for the selfie stick, allowing for smooth operation and preventing slippage. |

| External Microphones | The adapter should provide a secure mounting point for the microphone, ensuring the microphone is properly positioned and aligned for optimal audio quality. The design should minimize vibrations to prevent audio distortion. |

| LED Lights | Requires a mounting point with sufficient space for the LED light and appropriate positioning for optimal illumination. The design should allow for adjustment and positioning of the light source. |

| Close-up Filters | The adapter should provide a secure and stable mounting point for the filter, allowing for easy attachment and removal. The adapter’s design should accommodate the specific dimensions of the filter. |

Improvements with Adapter Use

The use of these adapters with various accessories leads to notable improvements. Tripods become more stable and secure, resulting in sharper images. External microphones provide enhanced audio clarity, crucial for recording high-quality audio. Selfie sticks enhance the convenience of capturing selfies and group photos. LED lights allow for more versatile low-light photography, while close-up filters improve image detail.

These are just a few examples of how 3D printed adapters can enhance the functionality and usability of the iPhone 13 Pro.

Maintenance and Durability

D-printed camera bump adapters offer a compelling alternative to traditional solutions, but their longevity hinges on careful consideration of materials and usage. Understanding the factors impacting durability allows users to maximize the lifespan of these adapters, ensuring continued protection for their valuable iPhone 13 Pro cameras. Proper maintenance is crucial to prevent premature wear and tear, preserving the adapter’s structural integrity and functionality.The durability of 3D-printed camera bump adapters is significantly influenced by the inherent properties of the chosen 3D printing material, the printing process itself, and the intended environment of use.

Factors like exposure to UV radiation, temperature fluctuations, and mechanical stress play a pivotal role in determining the long-term performance and structural integrity of these custom-designed components.

Factors Affecting Durability

The choice of 3D printing filament directly impacts the adapter’s resistance to wear and tear. Different materials exhibit varying degrees of strength, flexibility, and resistance to environmental factors. Post-processing techniques, like surface finishing and reinforcement, can also enhance the adapter’s overall durability. Additionally, the printing process itself, including layer adhesion and infill density, contributes to the adapter’s structural integrity.

Potential Issues and Solutions

One potential issue is the inherent brittleness of some 3D printing materials. This can lead to cracking or chipping under stress. Implementing surface finishing techniques, like sanding or smoothing, can minimize these risks. Furthermore, the design of the adapter itself plays a critical role. Robust geometries and stress-reducing features can significantly increase the adapter’s overall durability.

Using more robust materials and incorporating stress-reducing design elements are effective solutions.

Maintenance Recommendations

Regular cleaning is vital for maintaining the adapter’s aesthetic appeal and functionality. Gentle wiping with a soft, lint-free cloth and a mild cleaning solution will effectively remove dust, dirt, and fingerprints. Avoid using harsh chemicals or abrasive materials, which could damage the adapter’s surface. Storing the adapter in a protective case or container when not in use can further safeguard it from environmental damage.

I’ve been tinkering with a 3D printed adapter for my Backbone controller and iPhone 13 Pro camera bump. It’s a cool little project, but I’m also fascinated by the new experimental features YouTube Premium users are testing out, like youtube premium test multiple new experimental features. Hopefully, these features will translate into a more intuitive and enjoyable experience for everyone, and perhaps even improve the way I use my Backbone controller adapter with my phone.

I’ll keep you updated on my 3D printing progress!

Long-Term Durability of Materials

The long-term durability of a 3D-printed camera bump adapter is strongly linked to the specific material employed. Common 3D printing filaments, like PLA, ABS, and PETG, each have unique properties that influence their resistance to various environmental factors. PLA, for example, is generally more susceptible to breakage compared to ABS. Factors like temperature fluctuations and UV exposure will influence the degradation rate of different materials.

Material Lifespan Comparison

| Material | Expected Lifespan (Years) – Indoor | Expected Lifespan (Years) – Outdoor | Environment Notes |

|---|---|---|---|

| PLA | 1-3 | 0.5-2 | Susceptible to moisture and UV exposure |

| ABS | 3-5 | 2-4 | More resilient than PLA, but still affected by UV |

| PETG | 3-5 | 2-3 | Good balance of strength and flexibility; moderate UV resistance |

| Nylon | 5-7 | 3-5 | High strength and toughness; better outdoor durability |

Note: Expected lifespan is an estimation and can vary based on specific environmental conditions and usage patterns.

Safety and Regulatory Compliance

D-printed camera bump adapters for iPhones, while offering customization and potential functionality enhancements, must prioritize user safety and adhere to regulatory standards. Understanding the potential hazards and implementing appropriate safety measures are crucial for responsible design and manufacturing. Compliance with regulations ensures these adapters are safe for intended use and protects consumers from potential harm.Careful consideration of materials, manufacturing processes, and design parameters is essential to mitigate any risks associated with these adapters.

This section explores the safety aspects, regulatory compliance considerations, and appropriate materials to ensure the safe and reliable operation of 3D-printed iPhone camera bump adapters.

Potential Safety Hazards

D-printed camera bump adapters, if not designed and manufactured carefully, can pose several safety hazards. These include the potential for sharp edges or uneven surfaces, which could lead to cuts or abrasions during handling or use. Furthermore, improper material selection or inadequate printing parameters might compromise the structural integrity of the adapter, resulting in a failure during use, potentially causing damage to the phone or injury.

The impact of dropped devices, especially if the adapter compromises the phone’s stability, is also a significant concern.

Safety Precautions

Implementing appropriate safety precautions is critical to mitigate the risks associated with 3D-printed camera bump adapters. Using smooth, rounded edges in the design minimizes the risk of cuts or abrasions. Employing materials with appropriate tensile strength and ensuring proper printing parameters to achieve consistent structural integrity is essential. Thorough quality control checks throughout the manufacturing process, including rigorous testing of the adapter’s structural integrity and impact resistance, are vital.

Regulatory Compliance Considerations

Regulatory compliance is crucial for 3D-printed camera bump adapters. Compliance varies depending on the intended use and geographic location. Meeting these standards is essential to ensure the product’s safety and market viability. Factors like material certifications, product testing, and labeling requirements need careful consideration. Compliance with relevant safety standards, such as those pertaining to electrical safety (if the adapter involves any electrical components), mechanical strength, and chemical compatibility with the iPhone’s components, is mandatory.

Materials Meeting Industry Standards

Selecting appropriate materials is vital for ensuring the safety and reliability of 3D-printed camera bump adapters. Materials should be non-toxic, biocompatible (if direct contact with skin is anticipated), and demonstrate adequate strength and impact resistance. Materials like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid) are commonly used in 3D printing, but their suitability for specific applications depends on the required mechanical properties.

Ensuring the material’s compatibility with the iPhone’s components and adherence to relevant industry standards is paramount.

Table of Safety Considerations and Regulatory Compliance Standards

| Application | Safety Considerations | Regulatory Compliance Standards |

|---|---|---|

| General Use (iPhone Protection) | Sharp edges, structural integrity, material compatibility with iPhone, impact resistance | ASTM International standards, CE Marking (if applicable), local safety regulations |

| Professional Photography (Heavy-duty use) | Enhanced impact resistance, additional structural support, stability for heavier lenses or accessories | ASTM International standards, CE Marking (if applicable), local safety regulations, specific industry standards for photography accessories (if relevant) |

| Accessories Integration | Compatibility with accessories, material resistance to chemicals or solvents in accessories, stability | ASTM International standards, CE Marking (if applicable), local safety regulations, specific industry standards for accessory compatibility |

Cost Analysis and Material Selection

Creating a 3D printed iPhone 13 Pro camera bump adapter involves careful consideration of materials and printing methods. Cost-effectiveness is crucial, as is achieving the desired quality and durability for a functional and appealing product. This section delves into the cost analysis of various 3D printing materials, comparing different printing methods, and evaluating the factors influencing the overall cost of the adapter.

Material Cost Comparison

The cost of 3D printing materials significantly impacts the final price of the adapter. Different materials offer varying levels of strength, durability, and aesthetic appeal, each influencing the overall cost. Common 3D printing materials for prototyping and functional parts include PLA, ABS, PETG, and nylon. These materials vary considerably in cost, which is influenced by factors like material availability, market demand, and manufacturing processes.

| Material | Estimated Cost (USD/kg) | Pros | Cons |

|---|---|---|---|

| PLA | 15-30 | Biodegradable, relatively low cost, good printability, suitable for prototypes. | Lower strength and heat resistance compared to others. |

| ABS | 25-45 | Stronger and more heat resistant than PLA, good impact resistance. | Can be more challenging to print, may produce more fumes. |

| PETG | 20-35 | Good balance of strength, flexibility, and printability, suitable for functional parts. | Slightly more expensive than PLA. |

| Nylon | 40-70 | High strength and durability, excellent chemical resistance, good dimensional accuracy. | Higher cost, more challenging to print, may require specialized settings. |

Printing Method Cost Comparison

Different 3D printing methods have varying costs associated with the equipment, consumables, and overall process. FDM (Fused Deposition Modeling) is often the most cost-effective option for initial prototyping, while SLA (Stereolithography) and SLS (Selective Laser Sintering) offer superior quality but at a higher cost. The choice of method depends heavily on the required precision, complexity, and desired durability of the final product.

- FDM: Typically the least expensive method, as the required equipment is relatively less costly. However, FDM prints may not achieve the same level of precision or strength compared to other methods. The cost of filament varies based on the material and supplier.

- SLA: SLA prints generally offer higher precision and surface finish, but the cost of the equipment and resin is significantly higher. The resin cost often makes SLA more expensive in the long run, despite the superior quality.

- SLS: SLS produces high-quality, strong parts, but the cost of the equipment and powder material is substantial. This makes it a more expensive method, usually reserved for demanding applications.

Factors Influencing Final Adapter Cost

Beyond material and printing method, several factors influence the final cost of the adapter. Design complexity, the number of parts required, and the need for post-processing (e.g., sanding, painting) all contribute. The labor costs associated with design, printing, and assembly also play a role.

Ever since I started messing around with 3D printing a backbone controller iPhone 13 Pro camera bump adapter, I’ve been keeping an eye on tech news. Recently, I saw a cool update about Facebook Reels, with a test launch of a new app feature. This could be huge for content creators, and it might even inspire me to experiment with new ways to use my 3D printed iPhone 13 Pro camera bump adapter for gaming.

This 3D printed adapter is super handy for adding a backbone controller to my phone for better gameplay. facebook reels update app test launch Hopefully, this means I can share my gameplay footage even more efficiently.

Trade-offs Between Cost, Quality, and Durability

A critical consideration is the trade-off between cost, quality, and durability. A low-cost material might sacrifice durability, while a higher-quality material could increase the overall cost. For instance, using PLA, while cost-effective, might not offer the same impact resistance as ABS, which could be crucial for a camera bump adapter. Careful consideration of these factors is essential to create a product that meets both functional requirements and budget constraints.

Future Trends and Innovations

D printing technology is rapidly evolving, promising exciting advancements in the creation of customized camera bump adapters for smartphones. These innovations will likely influence material choices, manufacturing processes, and the overall design of these adapters, leading to increased functionality and user experience. This section will explore potential future trends in 3D printing and their impact on the development of these adapters.

Advancements in 3D Printing Technology

Significant improvements in 3D printing technology are expected to impact the creation of camera bump adapters. Increased resolution and accuracy in 3D printing will allow for the creation of more complex and intricate designs. This will enable the production of adapters with precise contours and minimal gaps, ensuring a secure and snug fit for various phone models. Simultaneously, advancements in multi-material printing will allow the incorporation of different materials within a single adapter, potentially creating a combination of strength, flexibility, and aesthetic appeal.

Furthermore, the integration of advanced software tools for design and simulation will enable designers to create more optimal and functional adapter designs, minimizing the need for extensive physical prototyping.

Emerging Materials and Applications

The emergence of new and improved 3D printing materials offers significant potential for enhancing the performance and functionality of camera bump adapters. Biocompatible materials, for instance, could open up possibilities for creating adapters that are both durable and safe for users. Furthermore, materials with improved thermal conductivity can help manage heat generated by the phone’s camera during prolonged use.

The use of lightweight yet strong materials will reduce the weight of the adapter, enhancing the user experience.

Innovations and Trends for the Next Five Years

Within the next five years, we can expect several key innovations in 3D printed camera bump adapters. Improved precision and speed in printing will enable faster turnaround times for custom-designed adapters. Additionally, the use of advanced sensors in 3D printers will provide real-time feedback during the printing process, further enhancing the quality and consistency of the finished product.

These advances will contribute to the development of more affordable and readily available custom-designed adapters.

Impact on the Industry

These innovations will likely impact the industry by increasing the availability of high-quality, personalized camera bump adapters. The integration of advanced materials will potentially lead to improved protection and durability for the phone’s camera system, especially in high-impact situations. Furthermore, the reduced cost and improved efficiency in manufacturing will increase the accessibility of these adapters to a broader consumer base, boosting market demand and encouraging further innovation.

Potential Future Trends

- Increased precision and resolution in 3D printing will enable the creation of more intricate and accurate camera bump adapters.

- Multi-material printing will allow for the integration of different materials within a single adapter, offering a combination of strength, flexibility, and aesthetic appeal.

- The use of advanced sensors in 3D printers will provide real-time feedback during the printing process, enhancing quality and consistency.

- The development of biocompatible materials will open up possibilities for creating adapters that are both durable and safe for users.

- Improved thermal conductivity in materials will help manage heat generated by the phone’s camera during prolonged use.

End of Discussion

In conclusion, the backbone controller iPhone 13 Pro camera bump 3D printed adapter is a versatile solution for enhancing mobile gaming and other accessory integrations. This adapter provides a compelling blend of functionality, aesthetic appeal, and practical considerations. Understanding the design, manufacturing, and application aspects empowers users to make informed choices and unlock the full potential of this innovative accessory.

The focus on safety, durability, and cost-effectiveness ensures that this guide provides a complete picture for any user considering this type of adapter.